3

10777 - GB-CZ-HU-PL-RO-RU - 0 - 04 / 07

1

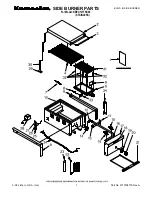

DESCRIPTION

This equipment complies with the following EC Directives:

- 73/23

Low Voltage

- 89/336

Electromagnetic compatibility

- 89/392

Machines

- 97/23

Pressure vessels (Article 3.3).

The burner should be fitted to the front of the boiler and

comprises:

- the burner head, inside the combustion chamber

- the air and fuel distribution system, outside the boiler

under a cover

The main parts of the burner are listed in the following

table and identified on the photograph below (without

cover).

Burner units are delivered in a package containing:

- a burner.

- pack of fittings comprising:

. fixing flange

. gasket

. nuts, bolts and washers

. nozzle

. wrench

. two hoses

. two nipples

. one electric connector

- documentation pack (instructions, boiler room plate,

warranty card, quality monitoring card).

This burner was designed to operate with domestic

fuel with viscosity at 20

°

C of between 2 and 7.5 cSt.

It is known that fuel viscosity greatly varies at low

temperatures. It is recommended that the tank and fuel

inlet and return pipes are protected against the cold.

Fuel of 5 cSt viscosity at 20

°

C switches to 10 cSt

viscosity at 0

°

and 15 cSt viscosity at -10

°

. Nozzle

spraying and flow are then fully changed and there is

a risk of clogging and breakdown.

V

T

H

D

A

B

L

C

S

J

U

G

I1

W

I

O

R

M

K

Q

N

P

F

E

1.2

One stage burner

Item

Description

Item

Description

A

Mounting screw for rear casing (4)

L

Line position setting screw (stabilizer / flare)

B

Photoconductive cell

M

Oil vacuum connector

C

Head air pressure connector

N

Oil suction

D

Programming unit

O

Intake

E

Programming unit base + connectors

P

Oil tank return

F

Electric igniter

Q

Oil pressure setting screw

G

Cover support square and maintenance position

R

Pump filter

H

Oil solenoid valve

S

Electric motor starter condenser

I

Maintenance position housing N° 1

T

Electric motor

I1

Maintenance position housing N°2

U

Intake locking screw

J

Oil pump

V

Air flap setting button

K

Oil pressure connector

W

Protective mesh