Banner Engineering Corp.

Vibration Monitoring Solutions Kit Quick Start Guide

Page 9

214301 Rev. C

Advanced Options

Install a Warning/Alarm light indicator

Add a tower light or indicator light (such as a K70, TL50, TL70, etc.) to the solution box for added local

indications of all clear, warnings, or alarms. The DXM Wireless Controller uses PNP outputs with a maximum of

100 mA per output so an interposing relay may need to be added to accommodate higher amperage lights.

To install:

1.

Carefully cut an appropriately sized hole in the box and mount the light accordingly. (Standard size is 30

mm diameter)

2.

Wire DC ground to the light or an interposing relay from the bottom row of the gray two-row terminal

blocks inside the Solutions Kit on the DIN rail adjacent to the DXM Controller.

3.

Wire the input of the light or interposing relay to the DXM as follows:

a.

O1 – Pin 5 – indicates any sensor/asset in Alarm or Out of Sync condition

b.

O2 – Pin 6 – indicates any sensor/asset in Warning condition

c.

O3 – Pin 7 – indicates any sensor/asset in either Warning, Alarm, or Out of Sync condition

d.

O4 – Pin 8 – indicates no Warning or Alarms conditions exist

Additional Vibration Information

The vibration solutions kit provides machine learning for baseline and alerting on RMS Velocity and High

Frequency Acceleration for both the X and Z Axis. However, the vibration sensor contains many additional

registers of vibration information that are stored in the local registers and can be polled by any host connected

to the same network or the data can be sent to the cloud. Below is a register list of the additional available

information.

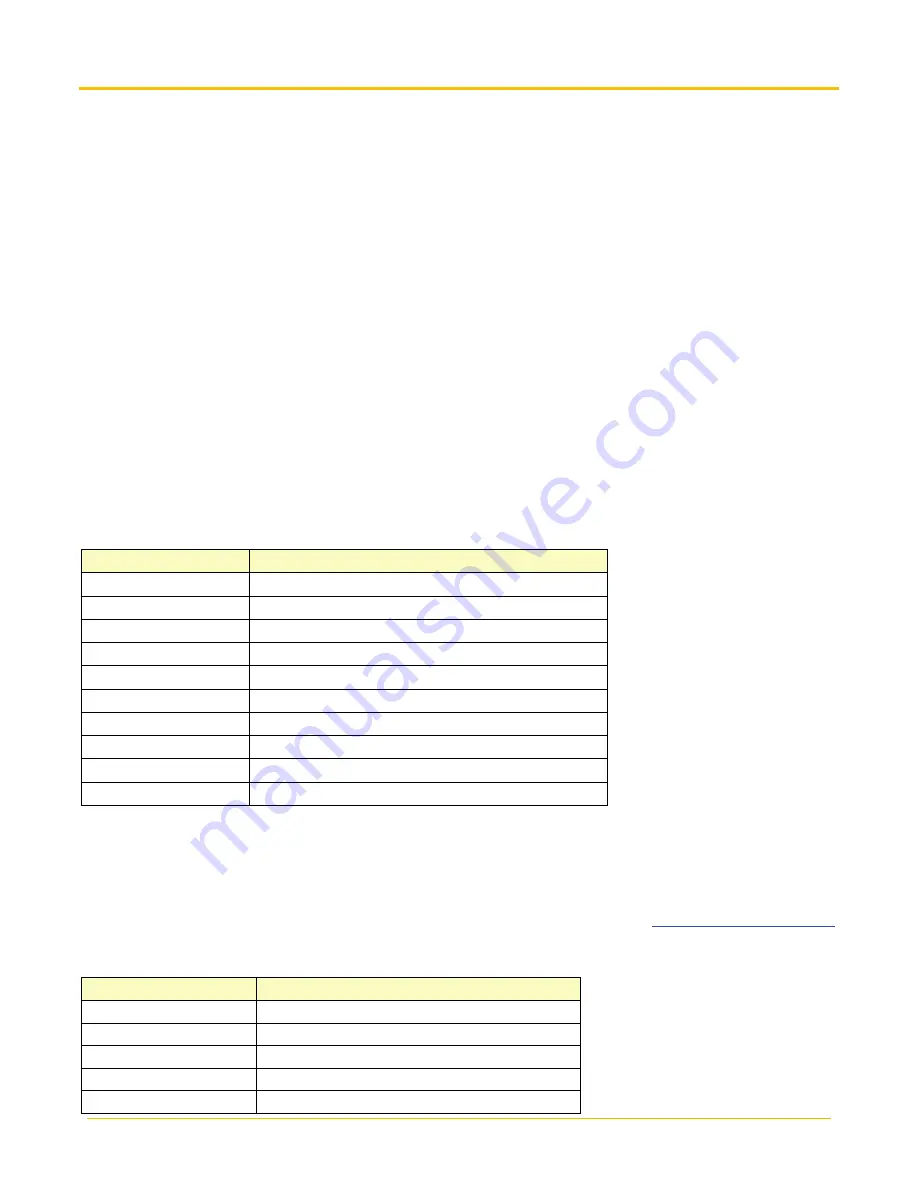

Register Number

Description

6141 + S × 10

Z Axis Peak Acceleration

6142 + S × 10

X Axis Peak Acceleration

6143 + S × 10

Z Axis Peak Velocity Frequency

6144 + S × 10

X Axis Peak Velocity Frequency

6145 + S × 10

Z Axis RMS Low Frequency Acceleration

6146 + S × 10

X Axis RMS Low Frequency Acceleration

6147 + S × 10

Z Axis Kurtosis

6148 + S × 10

X Axis Kurtosis

6149 + S × 10

Z Axis Crest Factor

6150 + S × 10

X Axis Crest Factor

Where S is the sensor number 1-40

In addition to this information, spectral banding information for three bands of each axis at 1x, 2x, and 3x-10x

the rotational speed of the motor is available based on a dynamic speed input. To use this feature, have a host

system or read rule from a MultiHop radio with speed input place the speed in Hz into registers 6581–6620

(Sensors 1–40) at a rate of no more than once per hour. Below is a list of the spectral band information that is

available in floating point registers 1001–1960. For more information, please read the

on the Vibration and Temperature sensor webpage. Only the default configuration of 1x, 2x, 3-10x is available on

the Solutions Kit.

Register Number

Description

1001 + S × 36

Z Axis Velocity 1x Band

1003 + S x 36

Z Axis Peak Velocity 1x Band

1005 + S × 36

Z Axis Velocity Peak Frequency 1x Band

1007 + S × 36

Z Axis Velocity 2x Band

1009 + S x 36

Z Axis Peak Velocity 2x Band