DIAGNOSTICS

Error No.

Error T

ype

Error No.

Error T

ype

—

System

OK

4

Emitter Error

1

Align

/ blank

5

Serial

Comm

2

Output

Short

6

EEPROM

3

E / R Mismatch

7

CPU Error

4

Receiver

Error

8

Null / Span

1

POWER

2 - TX

3 - RX

5 - COM

ALIGNMENT

SWITCH

DIAGNOSTICS

INDICA

TOR

RS-232

MAHCN-1

HIGH RESOLUTION MINI-AR

RAY CONTROLLER

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

+

NC

NC

10-30Vdc

GATE

NC

TX

TX

+12V

BR

EMTR

RCVR

BU

BK

5 Wires

WH

30V

150mA MAX

OUTPUT#1

COM

DRN

T/R

T/R

16-30V dc

1A MAX

POWER 2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

OUTPUT

ALARM

GA

TE

ALIGN

–

+

–

F1

30V(MAX)

150mA MAX

ALARM

10-30Vdc

ALIGN

RS-485

+

–

High-Resolution

Emitter

MAHCN-1

Control Module

High-Resolution

Receiver

Beam #1 of 64

Blocked

Beam #48

Clear

Beam #32

Blocked

Beam #44

Clear

Beam #40

Blocked

Beam #42

Blocked

Beam #43

Blocked

Step #2

Step #1

Step #3

Step #4

Step #5

Step #6

Step #7

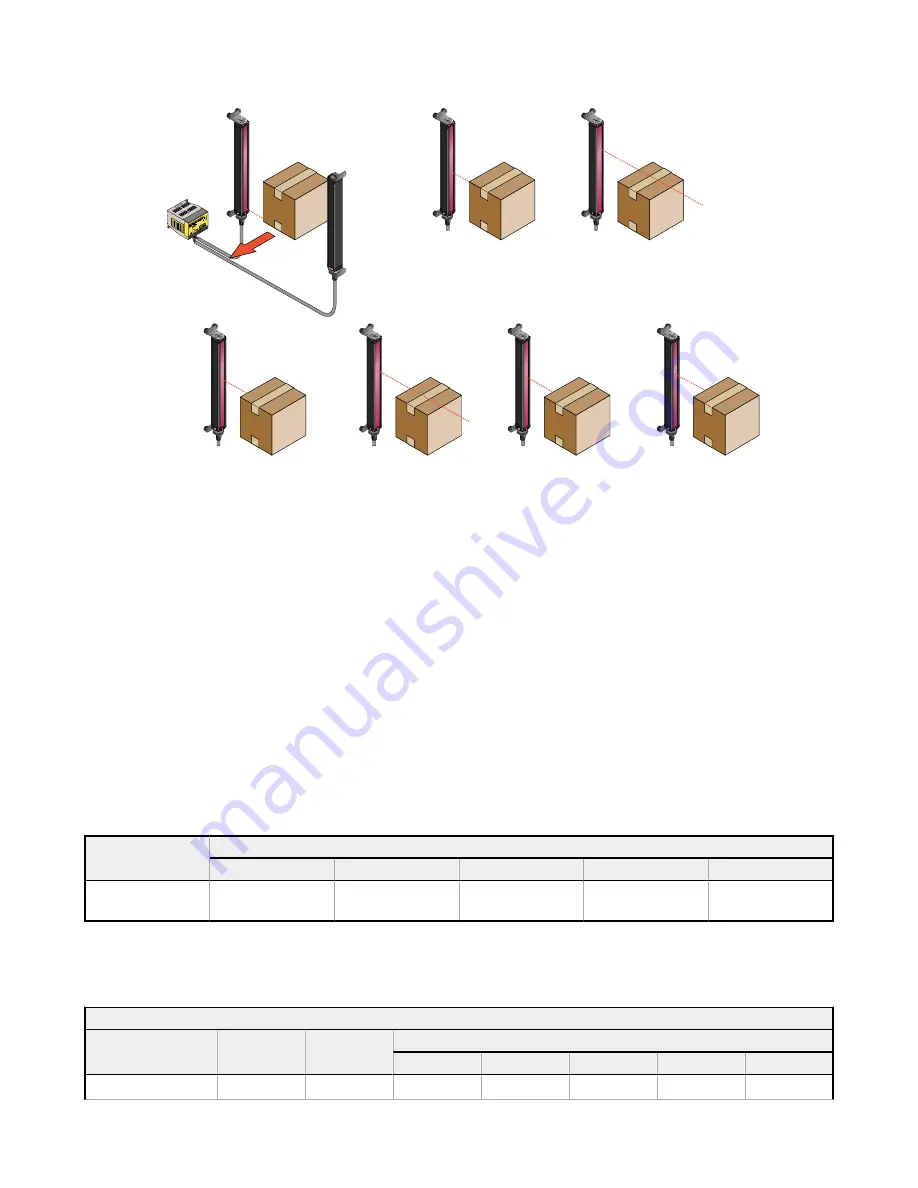

Figure 20. Finding an Edge Using a Binary Search

Note that the receiver always checks the bottom beam first, and only if that beam is blocked does the binary search

continue. Therefore, Single-Edge scan will not work in instances where an item that does not block the first beam is to be

measured. Single-Edge scan is also ineffective if the object does not present a continuous blocked pattern. In other words,

Single-Edge scan is used for single, solid objects that block the first beam.

Double-Edge scan is used to detect two edges of a single object, for example, box width measurements. Double-Edge

Scan requires the selection of a step size: 2, 4, 8, 16 or 32 beams. The sensor uses the steps to skip over beams. Double-

Edge scan works as follows:

1. The sensor activates beam #1 (the beam closest to the sensor cable end).

2. The sensor activates the next beam, determined by the step size. For example, if the step size is 2, beam #3 is next;

if the step size is 8, beam #9 is next.

3. As long as the activated beam is unblocked (or made), the sensor continues the stepping routine until a blocked

beam is found.

4. When a blocked beam is found, a binary search is conducted to find the object’s bottom edge.

5. When the bottom edge is found, the sensor begins stepping again through the array until the sensor finds the next

unblocked beam.

6. A binary search is again performed to find the second edge.

Note that this scanning method sacrifices object detection size for speed. Similar to Single-Edge scan, Double-Edge scan

has some restrictions: the object should provide a solid obstruction; the size of the object will determine the maximum step

size.

Table 1: The Effect of Step Size on Minimum Object Detection Size

Step Size

Number of Beams

2

4

8

16

32

Minimum Object

Detection Size

5 mm (0.2 in)

10 mm (0.4 in)

20 mm (0.8 in)

40 mm (1.6 in)

80 mm (3.2 in)

Sensor response time is a function of sensor length and scanning method. Typical scan times are shown in the following

table.

Table 2: The Effect of Sensor Length and Scanning Method on Scan Time (Typical)

Maximum Scan Time (in milliseconds)

Array Length

Straight Scan

Single-Edge

Scan

Double-Edge Scan

Step 2 Beams

Step 4 Beams

Step 8 Beams

Step 16 Beams

Step 32 Beams

163 mm (6.4 in)

5.8

1.8

4.8

3.4

2.7

2.5

2.6

A-GAGE

®

High-Resolution MINI-ARRAY

®

20

www.bannerengineering.com - Tel: + 1 888 373 6767