#656-253, Sungsu-1ka, Sungdong-ku, Seoul, Korea

TEL: 02-469-1239 / FAX: 02-497-1270 / E-MAIL: [email protected] / WEB SITE: www.banseok.co.kr

7. Maintenance and Cleaning

7. Maintenance and Cleaning

Normal cleaning is

accomplished by purging

with appropriate solvent. The

needle seat can be removed

(after the reservoir pressure

has been bled off) for

cleaning without demounting

the valve.

CAUTION:

CAUTION:

Always relieve

the reservoir pressure and

disconnect the power before

performing any maintenance

on the system.

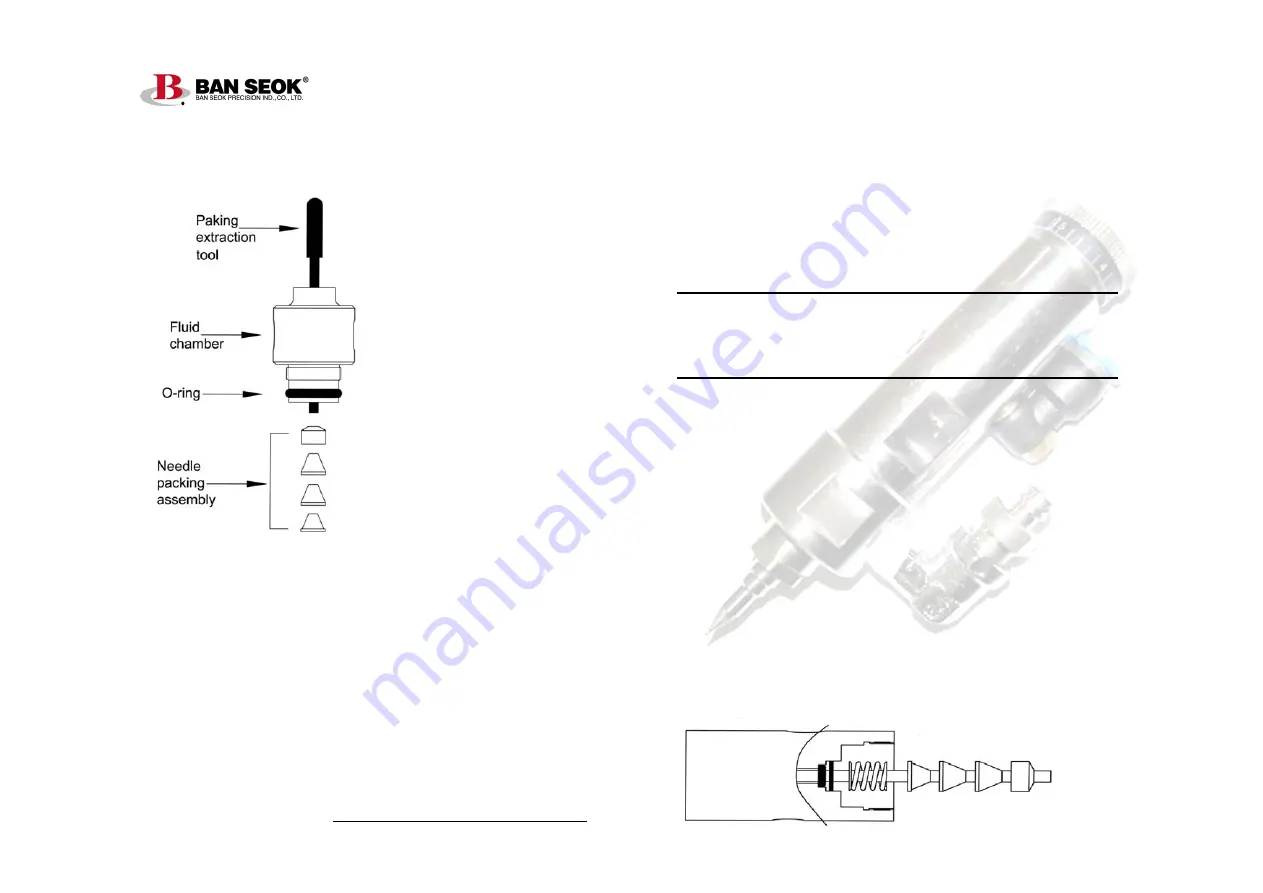

[Figure 2]

[Figure 2]

To thoroughly clean valve chamber and replace needle

packing:

1. Remove the needle stroke control and piston return spring to

prevent damage to the needle and seat during reassembly. Turn

counterclockwise until free.

2. Remove the inlet fitting and seat assembly from the fluid

chamber.

3. Remove the fluid chamber from the cylinder body by turning

counterclockwise until free. Then remove the O-ring from the fluid

chamber.

4. Remove the needle packings from the fluid chamber. Insert

through outlet end of the fluid chamber and gently push out the

packings (see Figure 1). – Packing extraction tool is not included.

[Figure 1]

[Figure 1]

Do not use sharp instruments to scrape or clean these

components. Scratches may cause the valve to leak.

5. Remove any remaining packings and the packing spring from

the needle.

Note:

The lower cylinder needle O-ring is held in place by a flat

retaining washer that also serves as the packing spring seat. The

washer may come out with the spring. Ensure that it is back in

place before reinstalling the packing spring (see Figure 2).

6. Clean the needle with a cloth dampened in solvent.

7. Lubricate the needle with lubricant. Reinstall the needle packing

spring and new packing kit in accordance with Figure 2.

8. Install a new O-ring on the fluid chamber. Screw the cylinder

onto the fluid chamber. Hand tighten only. The chamber can be

turned back out up to one turn to orient the fluid inlet fitting to the

desired position.

9. Reinstall the tip adapter/seat assembly.

10. To reinstall the piston return spring, first put one thrust washer

over the spring pilot (at the top of the piston), then the other thrust

washer into the needle stroke control, followed by the spring.

11. Reinstall the needle stroke control by aligning the piston return

spring with the spring pilot. Turn the needle stroke control

clockwise until it stops and then back it out the the desired setting.