Recirculated Water Quality Guidelines

can be adjusted using the valve in the bleed line and

measured by filling a container of known volume while

noting the time period. The bleed rate and water quality

should be periodically checked to ensure that ade-

quate control of the water quality is being maintained.

The required continuous bleed rate may be calculated by

the formula,

Evaporation Rate

Bleed Rate =

Number of Cycles of Concentration – 1

The evaporation rate can be determined by one of the

following:

1.

The evaporation rate is approximately 2 GPM per 1

million BTU/HR of heat rejection.

2.

The evaporation rate is approximately 3 GPM per 100

tons of refrigeration.

3.

Evaporation Rate = Water Flow Rate x Range x .001

Example: At a flow rate of 900 GPM and a cooling range

of 10°F, the evaporation rate is 9 GPM (900 GPM x 10°F

x .001 = 9 GPM).

Note: For Closed Circuit Cooling Towers, the flow rate to

be used in this calculation is the flow through the coil.

Note: The bleed line must be furnished by others on VTO,

VT1 and VTL cooling tower models.

If the site conditions are such that constant bleed-off

will not control scale or corrosion and maintain the

water quality within the guidelines, chemical treat-

ment may be necessary. If a chemical treatment pro-

gram is used, it must meet the following requirements:

1.

The chemicals must be compatible with the unit con-

struction (zinc-coated) steel as well as all other mate-

rials used in the system (pipe, heat exchanger, etc.)

2.

Chemicals to inhibit scale and corrosion should be

added to the re-circulating water by an automatic

feed system on a continuously metered basis. This

will prevent localized high concentrations of chemicals,

which may cause corrosion. It is recommended the

chemicals be fed into the system at the discharge of

the recirculating pump on open cooling loops. They

must not be batch fed directly into the cold water

basin. For Series V coil products, chemicals should

be metered into the recirculating water over the coil.

3.

Acid water treatment is

not recommended unless

the unit(s) have been furnished with the BALTI-

BOND® Corrosion Protection System or is con-

structed of Type 304 stainless steel - in which cases

acid treatment can be used provided the requirements

of paragraph 1 and 2 above are maintained.

SYSTEM CLEANING

Closed Circuit Cooling Towers

With proper precautions, alkaline solution used to clean

condenser water systems prior to start-up may be circulat-

ed through a Series V or Low Profile Series V Closed

Circuit Cooling Tower.

Water

Treatment

CORROSION AND SCALE CONTROL

In Evaporative Cooling Products, cooling is accomplished

by the evaporation of a portion of the process water as it

flows through the unit. As this water evaporates, the impuri-

ties originally present remain in the recirculating water. The

concentration of the dissolved solids increases rapidly and

can reach unacceptable levels. In addition, airborne impuri-

ties are often introduced into the recirculating water, intensi-

fying the problem. If these impurities and contaminants are

not effectively controlled, they can cause scaling, corrosion,

and sludge accumulations which reduce heat transfer effi-

ciency and increase system operating costs.

The degree to which dissolved solids and other impuri-

ties build up in the re-circulating water may be defined as

the cycles of concentration. Specifically, cycles of concen-

tration is the ratio of dissolved solids (for example – total

dissolved solids (TDS), chlorides, and sulfates) in the re-

circulating water to dissolved solids in the make-up water.

For optimal heat transfer efficiency and maximum

equipment life, the cycles of concentration should be

controlled such that the re-circulating water is main-

tained within the guidelines list below.

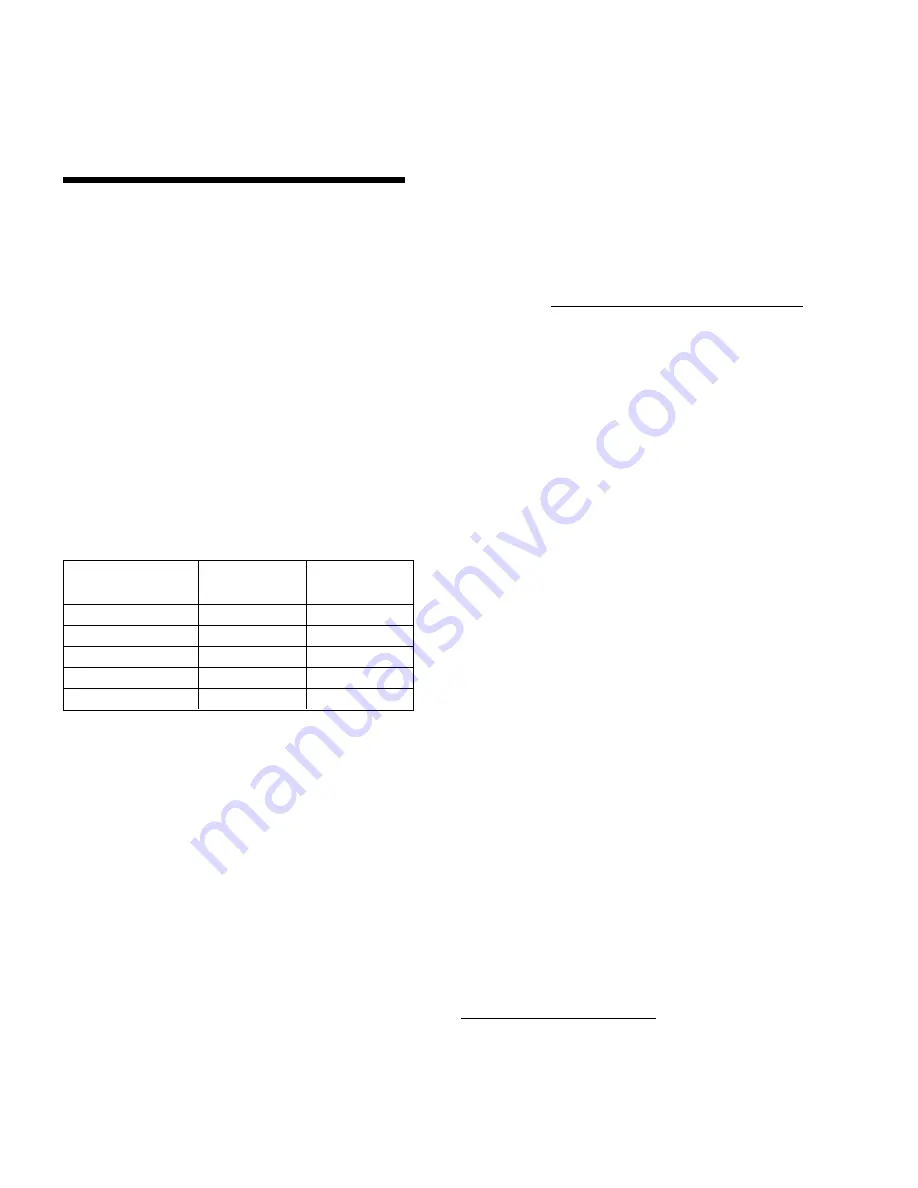

14

Galvanized

Steel

BALTIBOND®

Corrosion

Protection System*

pH

Hardness as CaCO

3

Alkalinity as CaCO

3

Total Dissolved Solids

Chlorides

6.5 to 9.0

30 to 500 ppm

500 ppm max.

1200 ppm max.

250 ppm max.

7.0 to 9.0†

30 to 500 ppm

500 ppm max.

1000 ppm max.

125 ppm max.

† Units having galvanized steel construction and a circu-

lating water pH of 8.3 or higher will require periodic pas-

sivization of the galvanized steel to prevent “white rust,”

the accumulation of white, waxy, non-protective zinc cor-

rosion products on galvanized steel surfaces.

* Closed Circuit Cooling Towers and Evaporative

Condensers with BALTIBOND® Corrosion Protection

System and hot-dip galvanized coils must use the water

quality guidelines for galvanized steel units.

In order to control the cycles of concentration such that

the above guidelines are maintained, it will be necessary

to “bleed” or “blowdown” a small amount of recirculating

water from the system. This “bleed” water is replenished

with fresh make-up water, thereby limiting the build-up of

impurities.

Typically the bleed is accomplished automatically

through a solenoid valve controlled by a conductivity

meter. The conductivity meter set point is the water

conductivity at the desired cycles of concentration

and should be determined by a competent water

treatment expert. (Note: The solenoid valve and conduc-

tivity meter must be supplied by others.) Alternatively, a

bleed line with a valve can be used to continuously bleed

from the system. In this arrangement, the rate of bleed