Maintenance & Troubleshooting 3-3

MN409

G40, G50 G315, G5000, G5810 Frames

Recommended Lubricant

Refer to the motor Lubrication nameplate for the type of lubricant to be used. If there is no Lubrication

nameplate on the motor, use the following lubricants:

G5000 & G315 Frames

−

Polyurea base hydrocarbon oil grease

G5810 & G40 Frames

−

Polyurea base hydrocarbon oil grease

G50 Frame

−

Lithium base hydrocarbon oil grease

Note: Lubrication nameplate on the motor takes precedent over this data. Use only clean, fresh grease

from clean containers.

Grease Lubrication Instructions

Anti

−

friction bearings may be lubricated with the motor running or stationary. However, stationary with the

motor warm is the preferred method.

WARNING:

Rotating parts can cause serious or fatal injury. If relubrication is performed with the motor

running, to avoid injury do not contact any rotating parts.

1.

Locate the grease inlet, remove all caked grease and dirt from the fitting.

2.

Remove relief plug. If grease is caked around the plug, clean with a wooden stick or suitable

tool. If severe caking appears at the plug, run the motor until the bearing housing is warm,

permitting free flow of grease through the housing.

3.

Add the recommended volume of the recommended lubricant per the motor Lubrication

Nameplate or Table 3-3 using a hand operated grease gun.

4.

Start the motor and run with the relief plug open for several minutes until all excess grease is

relieved.

5.

Replace plugs and wipe off any excess grease.

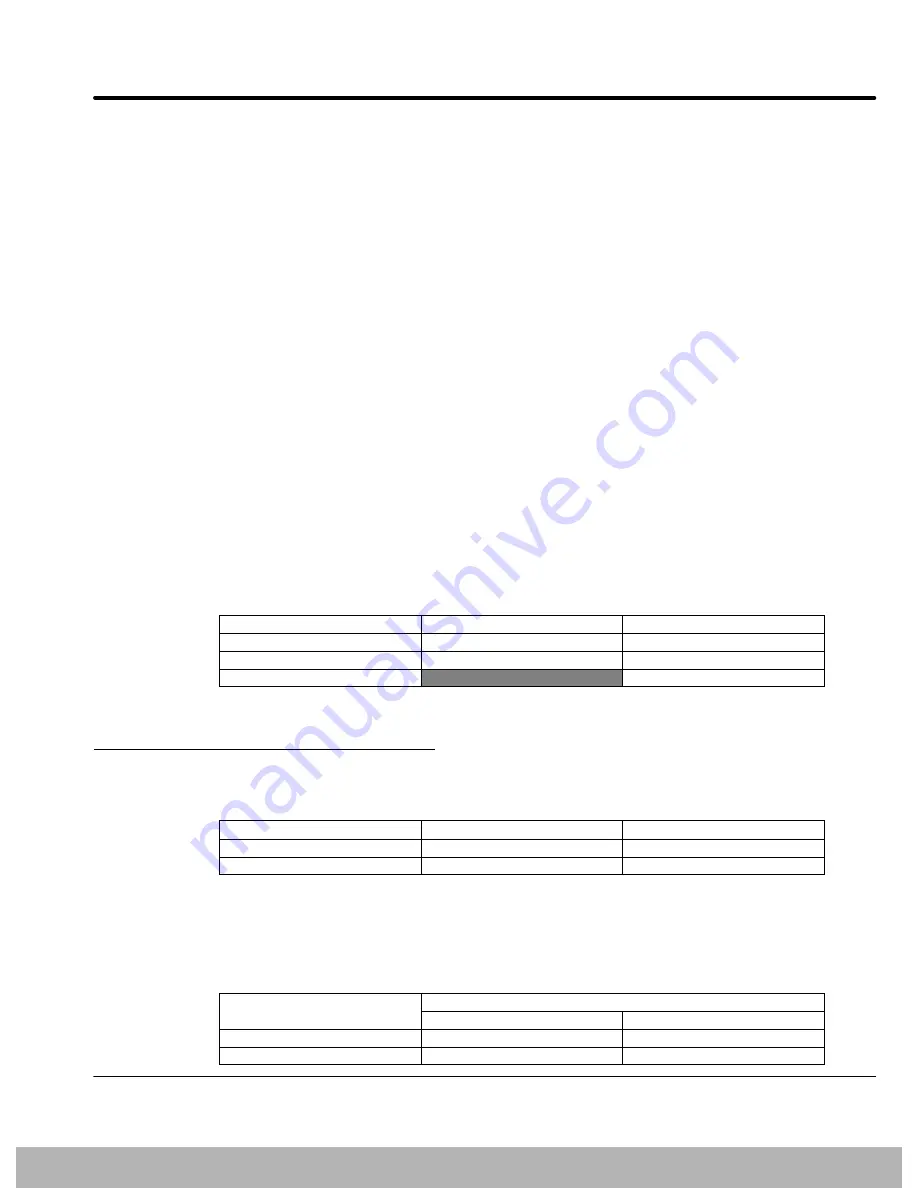

Table 3-3 Relubrication Volume

(cubic inches; Motor Maximum speed

−

RPM)

Frame Size

3000 & 3600

Less Than 3000

G5000 & G315

1.5

3.0

G5810 & G40

1.5

3.0

G50

4.0

Data contained on a lubrication nameplate on the motor takes precedent over this Table.

Sleeve Bearings (Oil Lubricated) Instructions

Oil should be changed periodically, or immediately if discolored or contaminated. Follow the schedule on

the motor nameplate, or if not known use the Table 3-4 schedule.

Table 3-4 Lubrication Schedule

Speed

−

RPM

Service Conditions

Change Oil (Hours)

All Speeds

Standard

8800

All Speeds

Severe

4400

Standard Conditions

: Normal or light loading, Clean, 0

°

F (

−

18

°

C)

to

104

°

F (40

°

C) ambient.

Severe Conditions

: Medium shock/vibration, Dirt/Dust,

−

20

°

F (

−

30

°

C)

to

120

°

F

(50

°

C) ambient.

Lubricant for sleeve bearing motors should be selected from Table 3-5.

Table 3-5

Ambient Temperature

Speed

−

RPM

1200 or less

Greater than 1200

0 to120

°

F (

−

18 to 50

°

C)

300 SUS (68 cST)

150 SUS (32 cST)

−

20 to 50

°

F (

−

30 to 10

°

C)

150 SUS (32 cST)

90 SUS (18 cST)

This Manual:http://www.manuallib.com/baldor/mn409-large-ac-motors-handbook.html

Содержание Global TEFC Series

Страница 15: ...2 6 Installation Operation MN409 This Manual http www manuallib com baldor mn409 large ac motors handbook html...

Страница 35: ...A 4 API Documentation MN409 This Manual http www manuallib com baldor mn409 large ac motors handbook html...

Страница 36: ...Baldor District Offices This Manual http www manuallib com baldor mn409 large ac motors handbook html...