Flushing Procedure

NOTE:

If the system has multiple dispense

positions, begin at the position farthest from

the pump and move towards the pump.

1. Close fluid dispense valves at every position.

2. Once the main fluid outlet valve at the pump is closed, the air pressure to the pump

motor is properly adjusted and the air valve is opened.

3. Slowly open the main fluid valve.

4. Place the hose end in a waste container. Make sure hose is secure so no fluid leaks

during flushing.

5. Slowly open the dispense valve and allow enough fluid to pass through it to ensure that

the system is clean.

6. Close the valve and repeat for all dispense positions.

Apply Meter to Hose

Close the drain valve before starting this procedure.

If this installation is new or if the fluid

in the lines is contaminated, flush the

system before installing the meter(s).

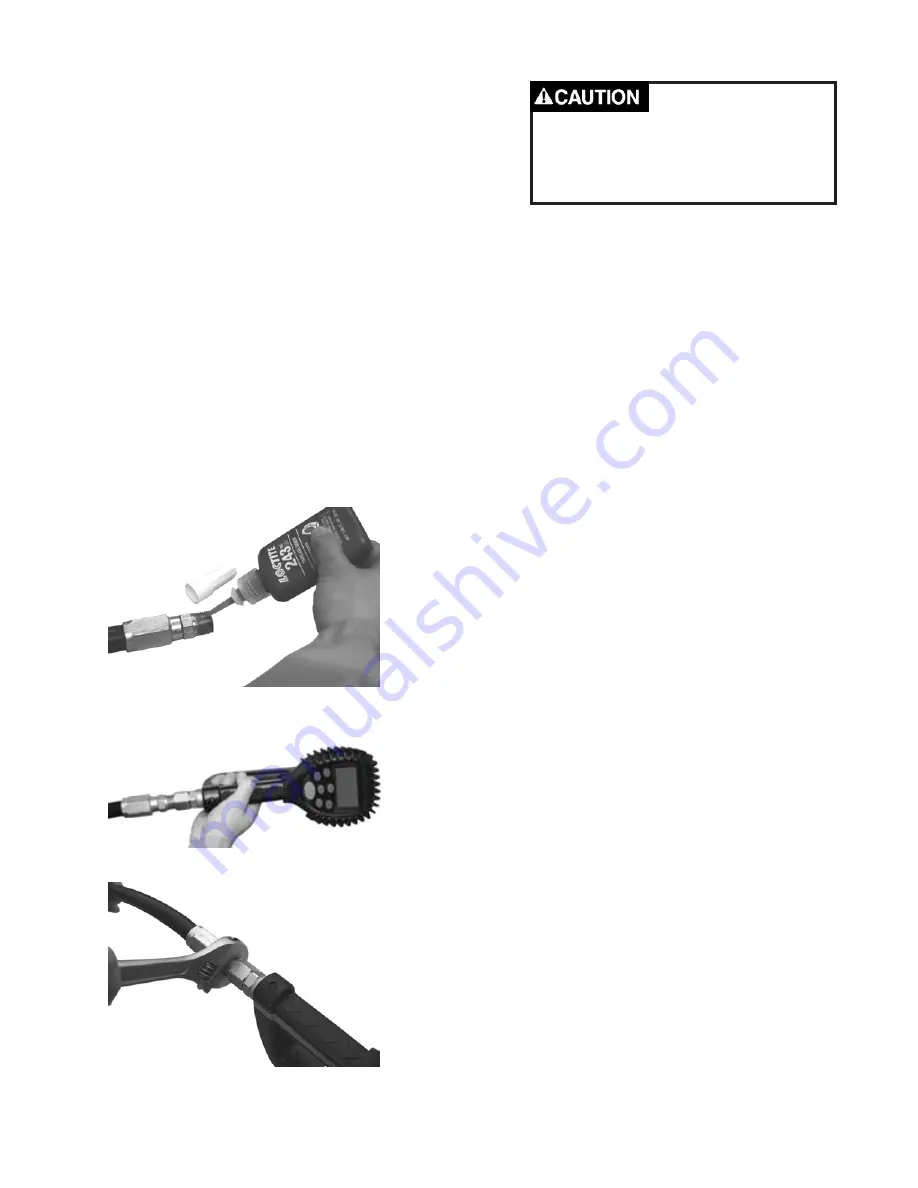

1. Attach a swivel to the meter. Apply thread sealant

to the male end of hose. Recommended sealant is

Loctite® 243.

2. Insert the metal end of the hose into the swivel.

Tighten completely with an open ended, adjustable,

wrench.

NOTE:

The threaded end of the meter always has

female threads. The metal end of the hose must

have male threads.

Apply thread sealant, Loctite® 243, or equivalent, to

the male end.

The inlet and outlet swivel connections are either

1/2” NPT or 1/2” BSPP, depending on meter model.

Attach the hose

3