31

31

LUBRICATION AND MAINTENANCE

•

Check daily for any unsafe conditions and fix immediately.

•

Check that all nuts and bolts are properly tightened.

•

On a weekly basis clean the machine and the area around it.

•

Lubricate threaded components and sliding devices.

•

Apply rust inhibitive lubricant to all non-painted surfaces.

Note: Proper maintenance can increase the life expectancy of your machine.

Daily Maintenance

•

Do a general cleaning by removing dust and metal chips from the machine.

•

Inspect the saw blade for wear.

•

Check that the blade guards and emergency stop button are in good working order.

•

When through using machine, lower the saw head to its rest position.

Weekly Maintenance

•

Thoroughly clean the machine.

•

Clean and grease the vise screw and sliding surfaces.

•

Clean the guard housing for the saw blade.

•

Driven pulley bearing should receive (6-8 drops of SAE-30 oil)

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

Содержание BS-128M

Страница 3: ...SAW VISE AND BASE PARTS DIAGRAM 37 Parts List 38 ELECTRICAL SCHEMATIC 43 TROUBLESHOOTING 44...

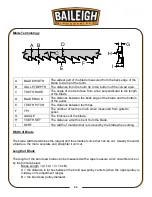

Страница 15: ...12 12 GETTING TO KNOW YOUR MACHINE S R Q P O N M L K J I H G F E D C B A...

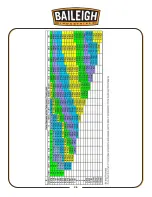

Страница 29: ...26 26...

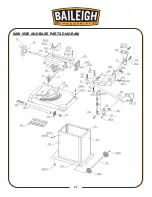

Страница 39: ...36 36 SAW BOW PARTS DIAGRAM...

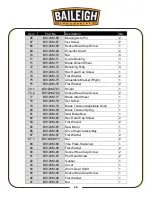

Страница 40: ...37 37 SAW VISE AND BASE PARTS DIAGRAM...

Страница 46: ...43 43 ELECTRICAL SCHEMATIC...

Страница 50: ...47 47 NOTES...

Страница 51: ...48 48 NOTES...