35

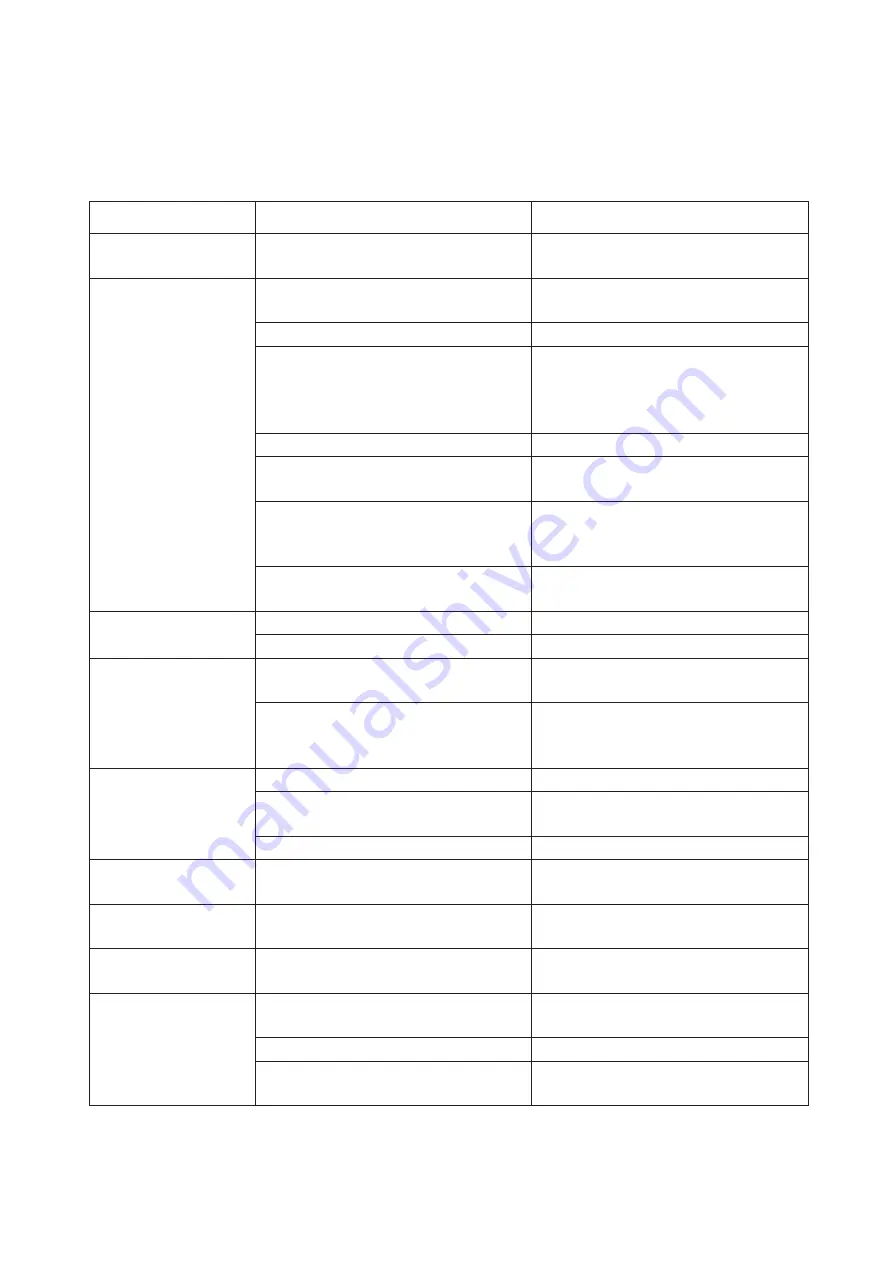

7-6. Troubleshooting

Symptoms of troubles, probable causes, and remedies are shown in the following table. For

adjustments, refer to the preceding section.

Symptom

Probable cause

Remedy

Pilot relay whines.

Stained valve stem (section hitting the port) Take out pilot relay and clean the valve stem

(section hitting the port)

No or only very low

controller output pressure

is delivered.

No air supply is provided or air supply

pressure is lower than 140 kPa {1.4 kgf/cm

2

).

Provide an air supply of correct pressure.

Restriction is clogged.

Take out and clean the restriction.

Restriction is not correctly installed.

Parts (restriction, blind plug, etc.) differ by

whether instrument is incorporated with

transmitter or not. Install correct parts at

correct positions.

Filter is stained.

Replace filter.

Air leak in nozzle circuit of controller unit. Check that O-rings are properly installed.

Securely tighten the controller unit.

Leak or clogging of A/M transfer circuit (for

instrument with A/M transfer provision)

Take out manual loader unit, inspect its

circuit, check that O-rings are properly

installed, and securely install the unit.

Leak in pilot relay diaphragm section

Take out pilot relay and inspect diaphragm.

If leak is found, replace diaphragm.

Controller output

pressure is too high.

Nozzle of controller unit is clogged.

Clean the nozzle.

Stained valve seat of pilot relay

Take out pilot relay and clean the valve seat.

Indication is with large

input offset.

SP or PV pointer is shifted.

Re-adjust deviation generating mechanism

and indicating mechanism.

Controller mechanism is not properly

adjusted. (Balancing of proportional band is

improper.)

Adjust balancing of controller mechanism.

Integral rate is shifted,

or integral action is

ineffective.

Damaged needle or seat

Replace needle assembly with new one.

Clamping screw of dial is loose.

Set the dial in the correct position and fix it

securely with screw.

Air leak of gasket

Securely fix to base.

Manual loading pressure

is low.

No air supply is provided or air supply

pressure is lower than 140 kPa {1.4 kgf/cm

2

}.

Provide proper air supply.

Manual loading pressure

is high.

Valve stem of pressure regulator valve is

stained or dusty.

Overhaul the pressure regulator.

Zero point shifts largely

when ranges are changed.

Transmitter section is not properly adjusted. Adjust and calibrate transmitter section.

Output is unstable or

pulsates.

Air leak

Check and correct air connections and

gaskets.

Stained nozzle/flapper

Clean the nozzle/flapper.

Stained pilot relay

Take out and clean the pilot relay. Replace it

as required.

Содержание KFDB

Страница 1: ...OM2 6220 0000 Field Mounted Indicating Controller Model KFDB KFKB KFLB User s Manual...

Страница 4: ......

Страница 7: ...3 Fig 1 2 Layout of Internal Components...

Страница 18: ...14...

Страница 27: ...23...

Страница 28: ...24...

Страница 38: ...32 Fig 7 2 Maintenance of Controller Unit...

Страница 42: ...36 Pneumatic Circuit Diagram...

Страница 43: ......

Страница 46: ......

Страница 48: ......