AB-6526

12

z

Piping

CAUTION

When installing this product, hold it in the

proper position and securely fasten it to the

pipes.

Excessive tightening or improper installation

position may damage the valve.

(1) Check that the model number of the product is

what you ordered. The model number is shown

on the label attached on the yoke.

(2) Install the valve so that fluid flows in the direction

pointed by the arrow on the valve body.

Refer to ● "Mounting position."

•

When piping, do not apply too much sealing

material, such as solidifying liquid and tape, to

the pipe connection sections.

•

Do not allow chippings, sealing material, etc. to

get into the pipes.

The foreign matter, such as chippings, seal

material for screwing the pipes, may be caught

in, resulting damages on the valve seat and the

valve may not be fully closed.

(3) Fully open the valve and flush the pipes at the

maximum flow rate. When fluid flows for the

first time, it is to clean out the foreign matter

and refuse in the pipes.

The valve is set to fully closed when it is shipped

from the factory.

CAUTION

After installation, make sure no fluid leaks

from the valve-pipe connections.

Improper piping may cause fluid leakage

outside of the valve.

Do not put a load or weight on this product.

Doing so may damage the product.

z

Heat insulation

•

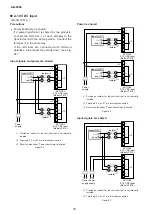

Apply heat insulation in the area illustrated by

in Fig. 6.

•

If the heat insulation material is placed above the

yoke, the indicator may be hidden from sight or be

deformed by being entangled with the insulation

material.

Heat insulation

Heat insulation

Figuar 6 Heat insulation

z

Factory preset position

Actuator shaft: fully closed

Pointer: completely turned counterclockwise

Pointer

Figuar 7 Pointer position for shipment