18

4.2 Tips for optimum performance

▲

Avoid using more than 10' of flexible hose on any ducting line. The ridges inside flexible hose

greatly increase static pressure loss, which reduces suction performance.

▲

Keep ducts between the dust collector and machines as short as possible.

▲

Keep ducting directional changes to a minimum. The more curved fittings you use, the greater the

loss of suction at the dust-producing machine.

▲

Gradual directional changes are more efficient than sudden directional changes (i.e. use 45°

elbows in place of 90° elbows whenever possible).

▲

The simpler the system, the more efficient and less costly it will be.

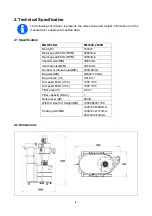

4.3 Required CFMs

Since each machine produces a different amount of sawdust, the requirements for the minimum

amount of CFM to move that sawdust is unique to the machine (for example, a planer produces more

sawdust than a table saw). Knowing this required CFM is important to gauging which size of duct to

use.

Refer to the figure below for a close estimation of the airflow each machine requires. Keep in mind

that machines that generate the most sawdust should be placed closest to the dust collector. If the

machine has multiple dust ports, the total CFM required is the sum of all ports.

Machine dust port Size

2" 2.5"

3" 4" 5" 6" 7" 8" 9" 10"

Approximate Required CFM

100 150

250 400 600 850 1200 1600 2000 2500

Содержание 107571

Страница 1: ...AW145CE Cyclone Extractor Code 107571 Original Instructions AT 09 02 2022 BOOK VERSION 01 ...

Страница 26: ...7 Diagram and part list 7 1 Diagram 23 ...

Страница 28: ...25 7 3 Wiring diagram 120V 60HZ 230V 50HZ 400V 50HZ ...

Страница 29: ......