Page 8-1

MAINTENANCE AND

LUBRICATION

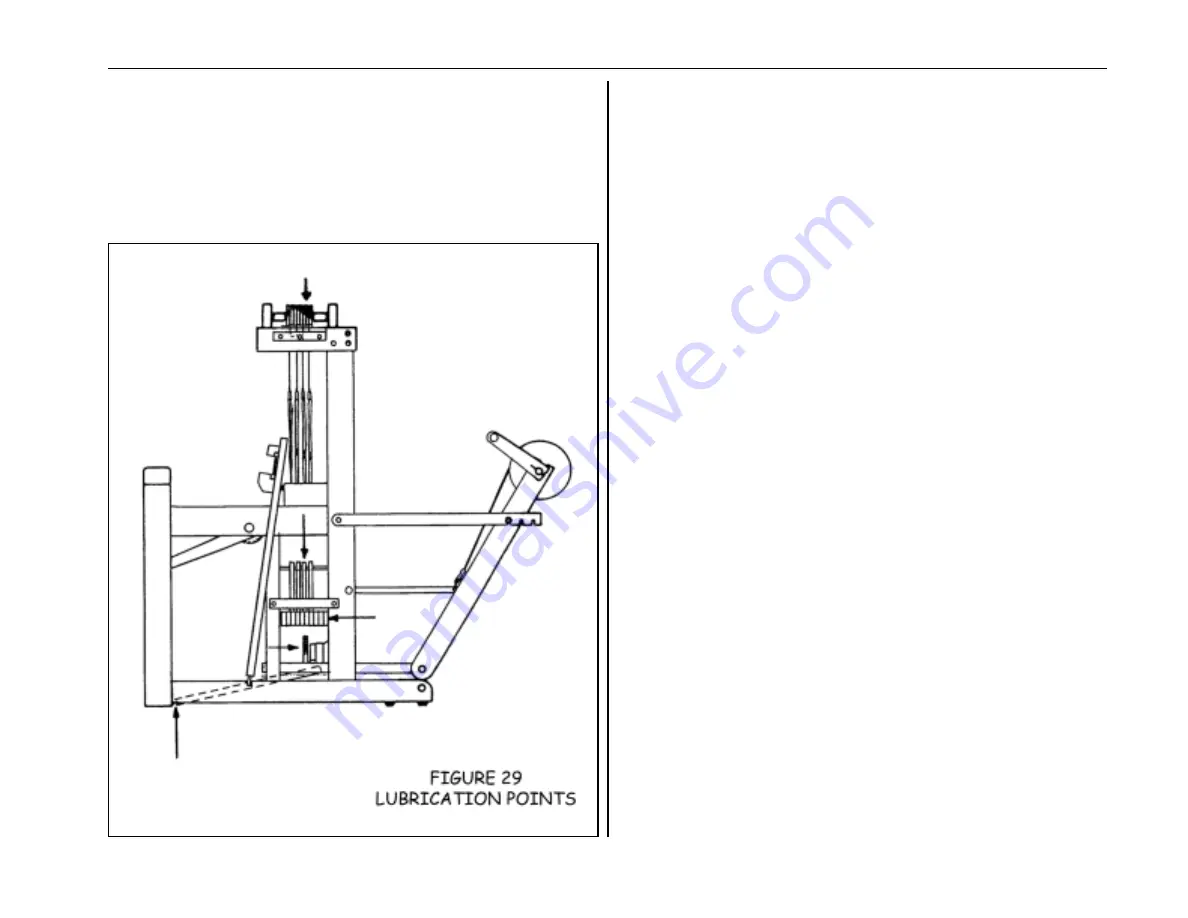

LUBRICATION

The AVL Home Loom has been designed and built to deliver many years

of trouble free service. A minimal amount of maintenance will be

required to insure that your loom will continue to perform properly

(refer to Figure 29). The arrows show the points on the loom which

should be oiled occasionally. Any light grade lubricant, such as sewing

machine oil, WD-40, or Tri-Flow teflon lubricant can be used. Make

certain that you never lubricate the brake cable or cord, especially where

it makes contact with the brake drum as this can cause tension problems.

FINISH

The AVL Home Loom has been finished primarily with semi-gloss,

water resistant lacquer. It should require no maintenance other than an

occasional dusting or application of furniture polish, if you wish to do so.

Minor touch up of a damaged lacquered finish can be accomplished by

simply applying a small amount of clear fingernail polish to the damaged

area. Larger repairs, should the need ever arise, should only be at-

tempted by a qualified repair person. Most of the lathe turned (round)

parts, as well as the harness sticks, have been finished with a natural

Danish oil. These parts, as the lacquered parts, require no special

treatment.