Page 3-2

Spring Levers

The springs of the spring lever return system should also be adjusted for

positive harness return, i.e., the harnesses stay all the way down in the

depressed position and require the least amount of effort for lifting. This

will vary according to the weight of the warp. In general, lightweight,

less dense, looser tensioned warps with a smaller weaving width will

need very little spring tension to assure positive harness return.

Heavier, denser, tighter tensioned, and wider warps will need more

spring tension. Attach the spring to the spring lever hooks, if you have

not already done so, using the last link in the chain to attach to the other

hook. To tell if the harnesses are returning all the way, open several

sheds by working the treadles. Watch the unlifted harnesses. If the tops

of their heddles become loose and tend to move around, then spring

tension should be increased, but just enough to get the harnesses to stay

down and no more, or your treadling effort will be made greater than it

has to be.

To adjust the spring tension, simply unhook the spring and then rehook it

one chain link shorter. This tightens the spring and makes it pull down

harder on that particular harness. Test the warp again by doing some

more treadling and if more spring tension is still needed, try one or

more chain links less. Under unusual conditions (perhaps a very tight rug

warp), two springs on some or all of the harnesses may be necessary. If

all the springs are set the same, the back harnesses will have a looser

tension than the front. This is because the back spring levers and their

hooks are longer since the back harnesses travel farther when a shed is

made. Accordingly, in some cases, the back spring levers might have to

be adjusted shorter to give the same tension as the front ones. The

important thing to remember is that the system is designed so that it can

be “fine tuned” for each particular warp, so experiment with it. In

general, for most medium tensioned warps, you will find that a lot of

adjusting will not be necessary.

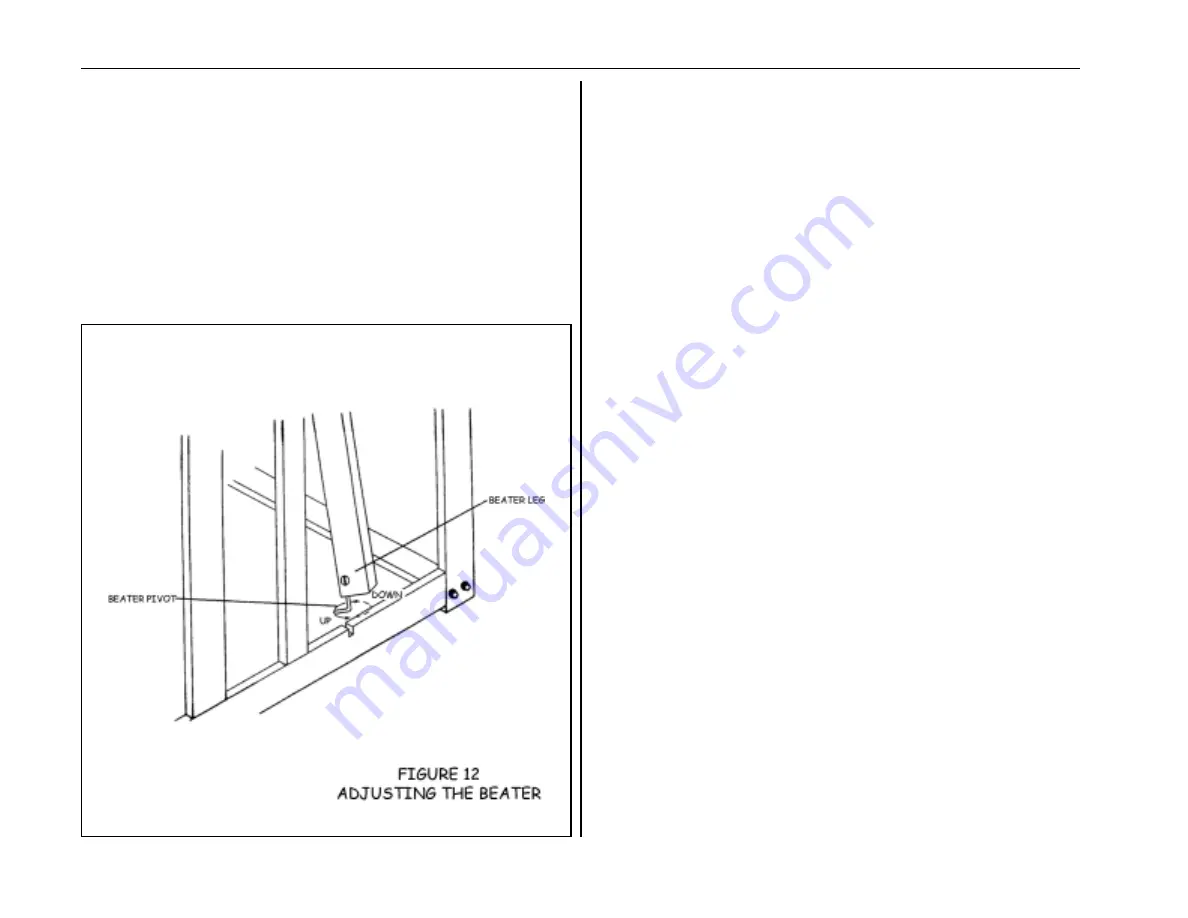

Beater Height

(refer to Figure 12)

The height of the beater is adjustable to compensate for different weav-

ing situations. Each leg of the beater can be lifted and the steel pivots can

be screwed into or out of the bottom of each beater leg, thereby chang-

ing how close the top of the shuttle race is to the warp. You should

always make this adjustment while the warp is under tension and the

beater is swung away from the weaver. Once this adjustment is made,

make sure that the steel pivots are put back into their notches at the

bottom of the loom.