Connecting the ejector pneumatics

W

Use only compressed air from an appropriately

maintained system (air or neutral gas in accordance

with EN 983, filtered to 5 μm, oiled or oil-free).

W

We recommend using external filters for high levels of

accumulated dirt on the suction end (dust, chips, etc.):

for example, VFI 6/4 for BV 07/10 and VFI 8/6 for

BV 15.

W

Dirt particles or foreign bodies in the ejector

connection or tubing or pipelines may impair the

ejector's function or lead to a malfunction.

W

Route tubing and pipelines as short as possible.

W

If the inside diameters selected for the compressed air

end are too small, the supply of compressed air will be

insufficient. As a result, the ejector will not achieve its

specified performance.

W

If the inside diameter selected for the vacuum end is

too small, this will cause an excessively high flow

resistance. This will in turn decrease the suction

capacity and increase the suction time. Blow-off times

will also increase.

W

Use only the tubing or pipe inside diameters that are

recommended for the ejector. If this is not possible, use

the next higher diameter.

Recommended inside diameters

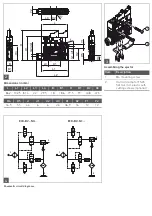

Make the pneumatic connection for the ejector as follows,

see Fig

:

1.

Make sure the relevant system part is not under

pressure.

2.

Lay the tubes so as not to bend or crush them.

3.

Connect the compressed air tubing with the

compressed air connection (

5

) and the vacuum tubing

with the vacuum connection (

4

).

CAUTION

System is under pressure during operation

Working on the system under pressure can lead to

injuries and damage to property.

O

Depressurize all relevant system parts prior to

performing work on the system.

ECD-BV-EC-...

Performance

class

Inside diameter [mm]

1)

1)

Based on a maximum tubing length of 2 m. In the case of

longer tubing lengths, select larger cross sections as

appropriate.

Compressed air

end

Vacuum end

07

4

4

10

4

4

15

4

6

4

1

3

Scope of Delivery

The scope of delivery includes:

W

1 compact ejector ECD-BV

W

Operating instructions

4

About This Product

Product overview

Fig.

shows compact ejector ECD-BV.

Function description

Vacuum generation (suctioning of workpiece)

The ejector is designed for handling parts using a vacuum

in conjunction with suctioning systems.

The ejector is actuated via the pilot valves. The “suction”

pilot valve activates and deactivates the Venturi nozzle. In

the NO variant, an applied voltage deactivates the Venturi

nozzle, while in the NC version it activates the nozzle.

On suctioned objects with leak-tight surface, the

integrated non-return valve prevents the vacuum from

dropping.

Blow off (placing down the workpiece)

The vacuum circuit of the ejector is pressurized with

compressed air via the “blow off” pilot valve. This mode is

used to ensure fast vacuum reduction and thus quick

placing of the workpiece.

Product description

Variants

Every ejector has an exact article designation

(e.g. ECD-BV-EC-07-NO). The breakdown for the article

designation is as follows:

O

Refer to the name plate of your variant for further

details, see figure

.

5

Assembly

Assembling the ejector

The ejector can be mounted either with screws or by using

a hat rail clamp, see Fig

and

.

See figure

for dimensions.

Type

ECD-BV

Operating mode:

electrical

EC

Via the pilot valve push-in fittings

Performance

class

07; 10; 15

Home position

NO

(normally open)

suction without

current

NC

(normally

closed) no

suction without

current

When mounting the fastening screws,

we recommend using washers.

1

1

1

3

1

3

1

3

1

2

AVENTICS

| ECD-BV | R412025988–BAL–001–AA | English

9