Maintenance schedule

16

MAINTENANCE SCHEDULE

Following table shows the maintenance and service points and intervals. There are more detailed instructions

about each service operation, in numerical order, on the following pages.

200 Series

LOADER

1. Clean the machine

2. Check tyre pressure

3. Check battery electrolyte level

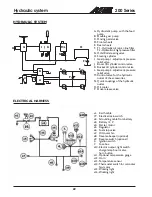

4. Check hydraulic oil level

5. Change hydraulic oil filters

6. Change hydraulic oil

7. Check tightness of bolts, nuts

and hydraulic fittings

8. Check pressure of hydraulic system

9. Adjust pressure of hydraulic system

10. Grease the machine

ENGINE*)

11. Check engine oil level

12. Change engine oil

13. Clean air filter

14. Clean fuel filter and

sediment cup

15. Clean spark arrester

16. Change spark plug

17. Change engine oil filter

18. Change air cleaner element

19. Check and adjust valve clearances

Every

week

Every

year

Every

1000 h

Every

800 h

Every

500 h

Every

400 h

Every

200 h

Every

100 h

After

50 h

After

25 h

Every

day

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

n

n

n

n

n

n

l

Maintenance operation

n

When necessary

*) More specific engine maintenance instructions can be found in the owners manual of the engine,

supplied with the loader.

l

Always secure the lifting boom with the

service support whenever working

under it. Make sure that the boom stays

up by putting the service support on

the lift cylinder piston rod.

The red service support is located under

the boom and fastened with a bolt

Make sure to secure the service support

by locking it on the piston rod by the

bolt

MOUNTING OF THE SERVICE SUPPORT