A-73

AC Type 2-Phase Closed-Loop Stepper Motor Driver

SENSORS

FIELD

INSTRUMENTS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Closed Loop

Stepper System

(B)

Stepper Motors

(C)

Stepper Motor

Drivers

(D)

Motion

Controllers

-|Transparent setting guide|-

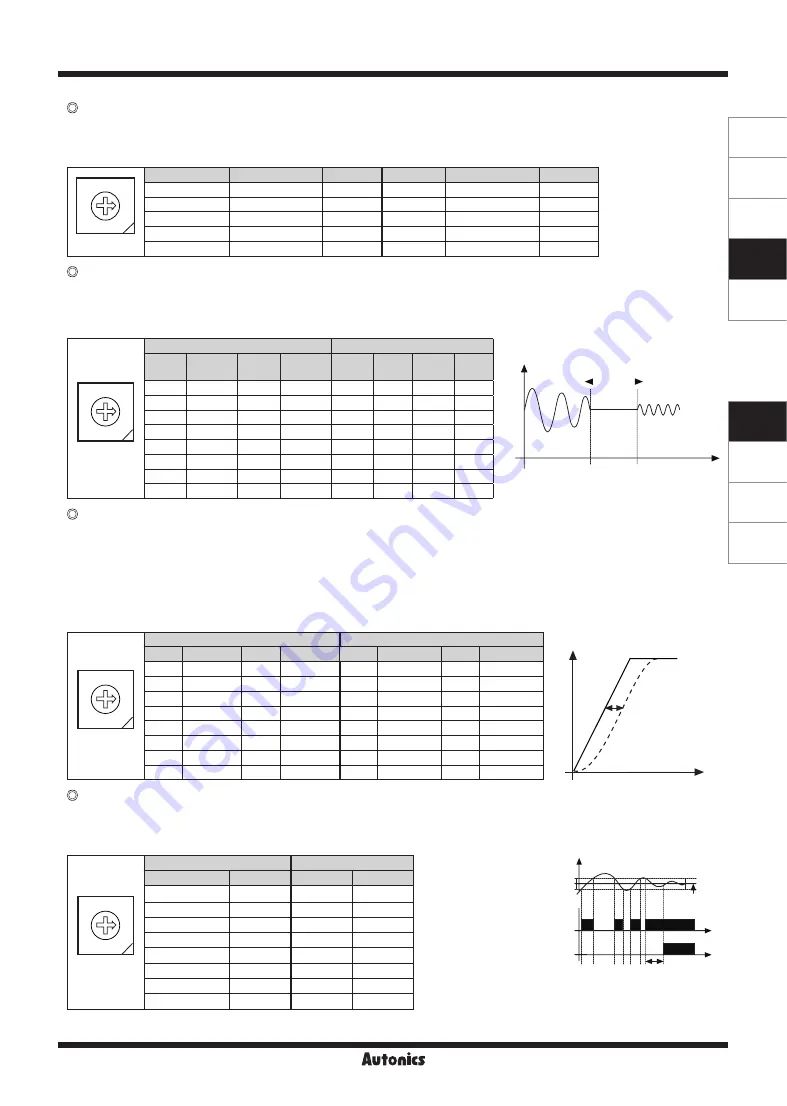

RES: Resolution setting switch

-Set the resolution of driver.

-The number of pulses per 1 rotation by resolution is each 500, 1000, 1600, 2000, 3200, 3600, 5000, 6400, 7200, 10000.

-Modified setting values are not applied in the running status, and the values will be applied after motor stopped.

5

0

1

2

34

6

7 8 9

RES

Setting

Pulse/Revolution Resolution Setting

Pulse/Revolution Resolution

0(factory default) 500

2.5

5

3600

18

1

1000

5

6

5000

25

2

1600

8

7

6400

32

3

2000

10

8

7200

36

4

3200

16

9

10000

50

GAIN: Motor gain setting switch

-Depending on GS H/L switch setting, the motor GAIN sets High or Low.

-Motor GAIN is selectable from 32 GAIN.

- The larger gain is, the more improved transient response becomes and the less error occurs.

※

At the lowest system load status, raise the gain value until motor vibrates and set to 1 to 2 level lower.

S.F: Speed Filter / Limit setting switch

-Depending on TM switch setting, speed filter and speed limit function can be set.

● Speed Filter

-In standard mode, it sets the delay time between the command position and the motor position.

- It determines the responsiveness of the motor to the command and smoothly follows the speed even if the load changes or disturbance occurs.

● Speed Limit

-In torque mode, it sets the speed limit.

- When the rotation speed reaches the speed limit value, the torque control may become unstable. Set value greater than the speed to be limited.

8

0

4

C

6

E

2

A

1

9

3

B D

5

7

F

GAIN

GS H/L OFF

GS H/L ON

Setting Standard

GAIN

Setting Standard

GAIN

Setting Inertia

GAIN Setting

Inertia

GAIN

0

×1

8

×9

0

×17

8

×25

1

×2

9

×10

1

×18

9

×26

2

×3

A

×11

2

×19

A

×27

3

×4

B

×12

3

×20

B

×28

4

×5

C

×13

4

×21

C

×29

5

×6

D

×14

5

×22

D

×30

6

×7

E

×15

6

×23

E

×31

7

×8

F

×16

7

×24

F

×32

8

0

4

C

6

E

2

A

1

9

3

B D

5

7

F

GAIN

Speed Filter (TM OFF)

Speed Limit (TM ON)

Setting Delay time Setting Delay time Setting Limit speed Setting Limit speed

0

Disable

8

60 ms

0

10 rpm

8

90 rpm

1

2 ms

9

80 ms

1

20 rpm

9

120 rpm

2

4 ms

A

100 ms

2

30 rpm

A

150 rpm

3

6

ms

B

120 ms

3

40 rpm

B

200 rpm

4

8

ms

C

140 ms

4

50 rpm

C

250 rpm

5

10 ms

D

160 ms

5

60 rpm

D

300 rpm

6

20 ms

E

180 ms

6

70 rpm

E

380 rpm

7

40 ms

F

200 ms

7

80 rpm

F

500 rpm

Speed

GAIN

Proper

GAIN

Over

Under

Status

INP: In-Position setting swtich

8

0

4

C

6

E

2

A

1

9

3

B D

5

7

F

INP

Fast response

Accurate response

Setting

Value

Setting

Value

0

(factory default) 0

8

0

1

±1

9

±1

2

±2

A

±2

3

±3

B

±3

4

±4

C

±4

5

±5

D

±5

6

±

6

E

±

6

7

±7

F

±7

In-Position

(fast response)

In-Position

(accurate response)

Time

Position

Delay time: 50ms

Command

position

Time

-

After position command pulse has finished, if the gap between target position and real position is under In-Position setting value, positioning

completion pulse is output.

-Modified setting values are not applied in the running status, and the values will be applied after motor stopped.

<Graph for input speed

and motor response>

Delay time

Motor position

Input pulse

position

Time

Position