TJ300

01

SAFETY PRECAUTIONS

Important: Read these instructions carefully. Note THE SAFE

OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS JACK CORRECTLY AND WITH CARE FOR THE PURPOSE

FOR WHICH IT IS INTENDED. Failure to do so may cause damage or

personal injury. Retain THESE INSTRUCTIONS for future use.

-

Ensure the jack is in sound condition and good working order.

Take action for immediate repair or replacement of damaged

parts.

-

Use genuine parts only. The use of improper parts may be

dangerous.

-

Locate the jack in a suitable, well-lit working area. Keep working

area clean and tidy and free from unrelated materials.

-

Use jack on level and solid ground, preferably concrete. Avoid

tarmacadam as jack may sink in.

-

Place wedges under wheels of vehicle, but ensure the jack

wheels are free to move and that there are no obstructions.

-

Ensure the vehicle handbrake is engaged, engine is switched

off and transmission is in gear (or “PARK” if automatic).

-

Ensure minimum distance of 0.5m between vehicle and static

objects such as doors, walls, etc., to allow for vehicle tilting.

-

Ensure there are no passengers in the vehicle and that all non-

essential persons keep a safe distance whilst the jack is in use.

-

Place jack under lifting points recommended by vehicle

manufacturer (see vehicle hand book). Ensure lifting point is

stable and centred on Saddle.

-

NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE

OF THIS PRODUCT.

Содержание TJ300

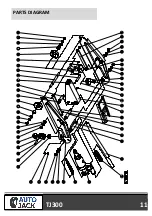

Страница 11: ...TJ300 09...

Страница 13: ...EP82 3 09 TJ300 11 PARTS DIAGRAM...