TJ300

04

Operation

The Owner and/ or operators shall

have an understanding of the

product, its operating characteristics

and safety operating instructions

before operating this device.

Safety information shall be

emphasized and understood. If the

operator is not fluent in English, the

product and safety instructions shall

be read to and discussed with the

operator in the operator’s native

language by the purchaser/owner or

his designee, making sure that the

operator comprehends their contents.

Inspection

a.

Visual inspection shall be made

before each use of the jack by

checking for abnormal

conditions, such as cracked

welds, leaks, and damaged,

loose, or missing parts.

b.

Other inspections shall be made

as per product operating

instructions.

c.

This jack should be inspected

immediately if the jack is

believed to have been subject to

an abnormal load or shock. It is

recommended that this

inspection be made by a

manufacturer’s or supplier’s

authorised repair facility.

d.

Owners and/or operators should be

made aware that the repair of this

equipment may require specialized

knowledge and facilities. It is

recommended that an annual

inspection of the product be made

by a manufacturer’s or supplier’s

authori

s

ed repair facility and that

any defective parts, safety labels or

signs be replaced with

manufacturers or supplier’s specified

parts.

Damaged Equipment

Any jack that appears to be damaged

in any way, is found to be worn, or

operates abnormally

must be

removed from service until repaired.

It is recommended that necessary

repairs are to be made by a

manufacturer’s or supplier’s authori

s

ed

repair facility, if repairs are permitted by

the manufacturer or supplier.

Alterations

Due to the potential hazards

associated with this type of equipment,

no alterations shall be made to the

product.

Attachments & Adapters.

Only attachments and/or adapters

supplied by the manufacturer shall be

used.

Содержание TJ300

Страница 11: ...TJ300 09...

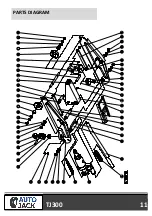

Страница 13: ...EP82 3 09 TJ300 11 PARTS DIAGRAM...