TJ300

05

Before use

a.

Before using

the

jack for the first

time, purge the hydraulic unit in

order to eliminate any air in the

system. Place handle (fig.1.H)

onto

the release valve (B) and

open

the

valve by turning the handle

anti-

clockwise, place handle back

into

the jacking point (A) and

pump for

30 to 40 seconds.

When complete,

close the

release valve by turning

the valve

(B)

clockwise. When lifting a load

of

maximum capacity or close to

it, it

is recommended that the

effort be

reduced by the use of

assistance

during this operation.

b.

Prior to each use, visual

inspection

is reccomended

by checking for

abnormal

conditions, such as

cracked

welds, leaks, and

damaged,

loose, or missing parts.

c.

Consult the vehicle owner’s

manual

to determine the location

of the

jack points.

d.

Be sure to set the vehicle in park

with the emergency brake on and

wheels secured and checked.

e.

Be sure that the vehicle and the

jack are on

a hard, level surface.

To Lift

1.

Turn the release valve clockwise

to the closed position. Do not

over tighten.

2.

Position the jack under the

specified lift point.

3.

Begin lifting by pumping the

handle up and down.

4.

Immediately after lifting, support

the vehicle with appropriate

rated jack stands.

5.

Turn the release valve slowly

counter clockwise to lower the

vehicle onto the jack stands.

To Lower

1.

Turn the release valve clockwise

to the closed position. Do not

over tighten.

2.

Pump the handle up and down

to lift the vehicle off the jack

stands.

3.

Remove the jack stands. Do not

get under or let anyone under

the vehicle while lowering.

4.

Turn the release valve slowly

counter clockwise to lower the

vehicle onto the ground.

Содержание TJ300

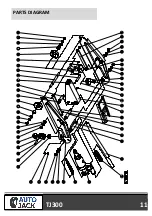

Страница 11: ...TJ300 09...

Страница 13: ...EP82 3 09 TJ300 11 PARTS DIAGRAM...