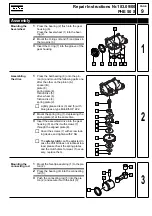

1

PAGE

Repair Instructions Nr.183.09/00

PHE 50 S

1

2

4

5

3

7

8

6

Special Tools

Require

■

Cone

4931 599 089

■

Forcing disks

4931 599 018

■

(Dis-) Assembly tool

4931 599 011

■

Allen key, long

4931 599 010

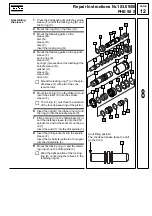

Important!

■

Before beginning the maintenance work, perform an initial check with a high voltage test according

to VDE (see chapter Electrical and Mechanical Test Instructions).

■

Before all repair work, pull the power plug from the socket!

■

Before dismantling, the machine must be connected to RTR-READER (maintenance measuring in-

strument) to check for a possible maintenance interval.

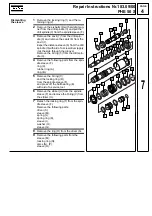

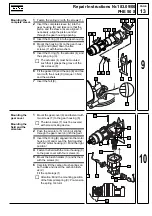

Disassembly

Detaching

the trigger

1

Loosen the screw (8) and remove the trig-

ger (7) with cover.

2

Loosen both screws (1) and remove the

motor cover (2).

3

Loosen the screws (3) and (5) and the dis-

tance sleeve (6).

4

Remove the complete handle (4).

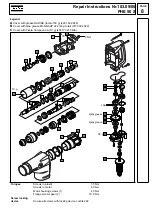

Dismantling the

auxiliary handle

1

Loosen the screw (2), remove the fan type

lock washer (1) and unscrew the han-

dle (3).

2

The following parts must be removed:

- screw off the clamping ring (4)

- support (5)

- push out the plastic cover (8),

- screw (7),

- clamping ring (6),

- depth gauge (9).

3

Push back the sleeve (B) and lever off the

cover cap (A).

4

Remove the sleeve (B).

5

Pull the gear housing insulation (C) from

the machine.

1

2

7

8

1

5

2

8

9

A

7

6

3

4

1

B

C

2

Содержание PHE 50 S

Страница 1: ......