Table 26 Inverter fault codes

Fault code

Condition

12

on page 123

8

on page 123

7

on page 124

33

CE - Modbus communication error

6

on page 125

28

on page 125

54

LF2 - Output current imbalance

27

on page 125

5

SC - Short circuit/IGBT failure

on page 126

2 or 60000

on page 126

3 or 60000

Uv2 - Control power undervoltage

on page 126

4 or 60000

Uv3 - Soft charge answerback fault

on page 126

17

EF3 - External fault(terminal S3)

59

STO - Safe Torque Off function activated

For other fault codes, contact us.

Fault

oL2 - Drive overload

Cause

The load is too large.

Remedy

Decrease the load.

Cause

The acceleration/deceleration times or cycle times are too short.

Remedy

Contact us.

Cause

Phase loss in the input power supply is causing the output current to

change.

Remedy

Correct errors with the wiring for main circuit drive input power.

Make sure that there is no phase loss and repair problems.

Cause

Pump restarted when it is still hot.

Remedy

Wait for 60 minutes and restart the pump again. If the pump does not start,

contact us.

Fault

ov - Overvoltage

Cause

The deceleration time is too short and too much regenerative energy is

flowing back into the drive.

Remedy

Contact us.

Cause

The acceleration time is too short.

Remedy

Contact us.

07/2021 - ©Atlas Copco

Page 123

1950840208_A

Fault finding

Содержание DWS 450 VSD+

Страница 1: ...Dry Screw Vacuum Pump DWS VSD INSTRUCTION MANUAL 1950840208_A Original instructions ...

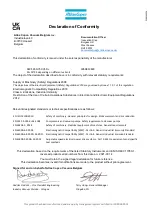

Страница 132: ...14 Legal declarations ...

Страница 137: ...atlascopco com ...