MAINTENANCE

Drive Sprocket Rollers

56

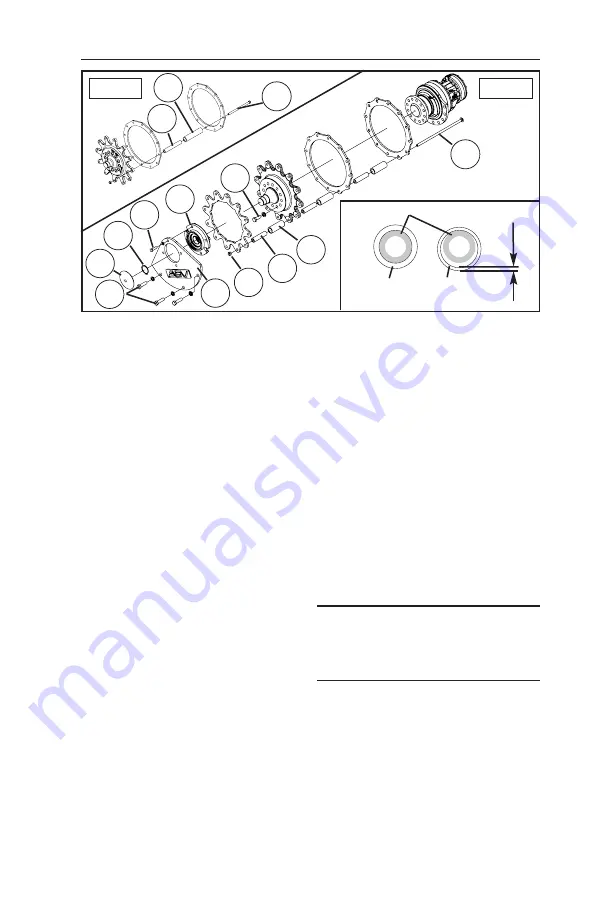

Drive Sprocket Rollers

ASV rubber track loaders utilize

rollers on the drive sprockets to

drive the track. These rollers

help minimize friction between

the track and the drive sprocket

to prolong track life.

The rollers rotate around hard-

ened steel pins and usually wear

on their inside surfaces. As they

wear, the rollers become thinner,

but will continue to function as

long as they rotate freely around

the pins. Sprocket rollers should

be inspected every 50 hours of

operation and replaced if

cracked or worn to less than

35% of original thickness. (.088”)

To replace worn rollers:

1.

Begin by performing steps 1-

4 in the track removal proce-

dure on page 52 to allow the

sprocket to be removed.

2.

Remove the seven bearing

plate mounting bolts (A, I),

then remove the plate (B)

from the drive table.

3.

Remove the bearing cap

(G) by tapping around the

bulged area of the cap with

a hammer. This will relieve

the outward pressure on the

cap and allow for removal.

4.

Remove the external snap

ring (H) from the bearing

shaft.

5.

Using a puller, remove the

bearing assembly (J) from

the shaft.

6.

Remove the sprocket

mounting bolts (C), then

remove the sprocket.

Note:

You may need to pry or lift

the track upwards with a hoist

above the drive sprocket to pro-

vide clearance for removal.

7.

Remove one bolt (F) holding

the steel pins (D) and rollers

(E) in place. Install the new

rollers over the pins, then

slide the bolt back through

the sprocket and pins and

secure it with the nut (K).

A

H

F

E

D

New Roller Normal Wear

35% life

Steel Pin

(.088”)

C

PT-70

D

E

F

PT-80

J

I

G

B

K

Содержание PT-80

Страница 6: ...5 ...

Страница 14: ...13 ...

Страница 32: ...31 ...

Страница 68: ...SERVICE LOG 67 Hours Service Performed Notes ...

Страница 69: ...SERVICE LOG 68 Hours Service Performed Notes ...

Страница 70: ...SERVICE LOG 69 Hours Service Performed Notes ...

Страница 71: ...SERVICE LOG 70 Hours Service Performed Notes ...