Page 50

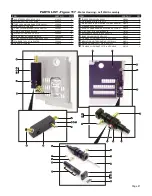

FINAL INSPECTION AND TESTING -

Procedure for Aseptico AEU-525CF - F-4.10-02-B

(Testing specs subject to change. Refer to latest Schematic

Drawing Set, PN 420991, Sheets 16-18 for updates.)

EXAMINATION FOR DEFECTS:

• Unit design, construction, operation, and performance not

as specified.

• Hardware components such as pins, screws and

fasteners missing, broken or otherwise damaged.

• Finish not as specified.

• Damage or defects on exterior or interior surfaces

present.

• Plating missing which effects function. Plating not free

from blisters, peeling, visible porosity, or other defects.

• Any component fractured, broken punctured, torn,

bowed, deteriorated, or malformed.

• Any component misplaced or not in proper alignment.

• Fastening device requiring loosening or removal is

swaged, peened, staked, or otherwise permanently

fastened, components missing.

• Components do not fit or mate properly.

• Interface fits between components not proper (too loose;

too tight/binding).

• Components not free from defects.

• Removable components cannot be removed or replaced

without difficulty.

• Coarse machine, tool or die marks present.

• Surface not clean, not free of foreign matter, flux or other

defects.

• Damage or defects on exterior or interior surface present.

• Operating instructions not provided.

• Service data not provided.

• Identification markings not present, not complete, not

permanent, not correct.

TEST PROCEDURE - NEW AND REPAIRED

PRODUCTS:

A.

Assemble AEU-525 with all instruments in their holders,

plug the power cord into 115VAC, 60Hz, and set the

voltage selector to “115”.

B. Performance Test (Suction):

1.

Make sure all instruments are in their holders, and

power switches are “ON”, and turn holder switches to

“OFF”. DO NOT latch the side latches of the Waste

Tank Lid. The Lid sealing gasket should just rest on top

the Waste Tank.

2.

Remove the HVE from its holder and turn on the

holder switch. The compressor should come on

continuously and there should be vacuum at the end of

the HVE. Check the maximum vacuum and the free air

flow rate. If < 3.9 SCFM @ 54” WC, remove power for

1 hour and repeat. If still low, mark as non-conforming.

Return HVE to its holder and turn the holder switch off.

3.

Remove the LVE from its holder and turn on the

holder switch. The compressor should come on

continuously and there should be vacuum at the end of

the LVE. Check the maximum vacuum and the free air

flow rate. If < 1.2 SCFM @ 20” WC, mark as non-

conforming. Return LVE to its holder and turn the holder

switch off.

4.

Turn the Purge/Pressure switch to ‘Purge’ and

remove the water bottle. There should be no air leaking

from the bottle cap. Switch the Purge/Pressure switch

to ‘Pressure’ and verify that there is air flow from the

bottle cap. Switch to ‘Purge’ and replace the water

bottle.

C. Performance Test (Line Voltage Select):

1.

Turn off the compressor power switch and allow all

the air to bleed from the system.

2.

Plug the power cord into 230VAC/50Hz and set the

voltage selector to “230”. Turn on the power switches

and run the compressor until it stops. Remove the HVE

from its holder and turn it on to start the compressor

again and run for 15 seconds and then turn off the

compressor power switch and allow all the air to bleed

from the system. Replace HVE in its holder.

D. Performance Test. (Air):

1.

Turn on the compressor to fill the air reservoir. Wait

two minutes to ensure there is no leakage. The

compressor should not come on sooner than every 30

seconds after the first two cycles. Check that the

pressure gauge reads 45-55 PSI.

2.

Operate the air syringe with a duty cycle of 20

seconds on and 10 seconds off for 5 minutes to check

for any possible stalling of the compressor.

E. Hand Motor Test:

1.

If the power is on, turn it off. Now turn on the power

while watching the LCD display and verify that the

software versions are “127” and “11”.

2.

Ensure the Standby button turns the display on and

off.

3.

Ensure the ratio button causes the display to cycle

through the ratio settings of 1:5, 1:2, 1:1, 5:1, and 8:1.

Set the console to the 1:1 ratio.

4.

Ensure the Torque Adjust buttons allow adjustment of

the display up and down from 5% to 100%. Set the

torque to 100%.

5.

Ensure the Speed Adjust buttons allow speed

adjustment up and down from 2.00KRPM to 40.0KRPM.

Set the speed to 2.00KRPM.

6.

Put a 20:1 handpiece with a large bur of some kind

on the motor. Press the footpedal and verify that the

bur rotates counterclockwise when viewed from the bur.

Release the footpedal and press the motor direction

button and verify that it goes from “FWD” to ”REV” and

back to “FWD”. Set it to “REV” and press the footpedal

and verify that the bur is now turning clockwise when

viewed from the bur and that the console is beeping.

Release the footpedal.

7.

Change the ratio to 8:1 and the torque to 5%. Now

press the motor direction button and verify that it goes

from “FWD” to ”REV” to “ENDO” and back to “FWD”.

Set it to “ENDO” and press the footpedal and loosely

grasp the slowly turning bur until you hear a beep and

the direction of the bur will briefly reverse and then

continue in the original direction.

8.

Remove the handpiece and press the “sun” symbol

until the LED turns on. Press the Torque Adjust buttons

to verify that the light intensity varies from very bright to

much dimmer. Leave the intensity at 100% and press

the “sun” symbol to turn off the LED. Press the “sun”

symbol to turn on the symbol on the LCD display and

press the “PRESET” button until there is a beep and the