Ascon Tecnologic - K31D - OPERATING INSTRUCTIONS - PAG. 5

instrument and that the load current absorption is no higher

than the maximum electricity current permitted.

As the instrument is a built-in equipment with permanent

connection inside housing, it is not equipped with either

switches or internal devices to protect against current

overloads: the installation must include a two-phase circuit-

breaker, placed as near as possible to the instrument, and

located in a position that can easily be reached by the user

and marked as instrument disconnecting device which inter-

rupts the power supply to the equipment.

It is also recommended that all the electrical circuits con-

nected to the instrument must be protect properly, using

devices (ex. fuses) proportionate to the circulating currents. It

is strongly recommended that cables with proper insulation,

according to the working voltages and temperatures, be used.

Furthermore, the input cable of the probe must be kept separat-

ed from line voltage wiring. If the wiring cables are shielded is

recommended to connect the shield to ground at one side only.

For the electrical supply of the instrument it is recommended

to use an external transformer TCTR, or with equivalent fea-

tures, and to use only one transformer for each instrument

because there is no insulation between supply and input.

m

We recommend that a check should be made that the

parameters are those desired and that the application

functions correctly

before connecting the outputs to

the actuators

so as to avoid malfunctioning that may

cause irregularities in the plant that could cause dam-

age to people, things or animals.

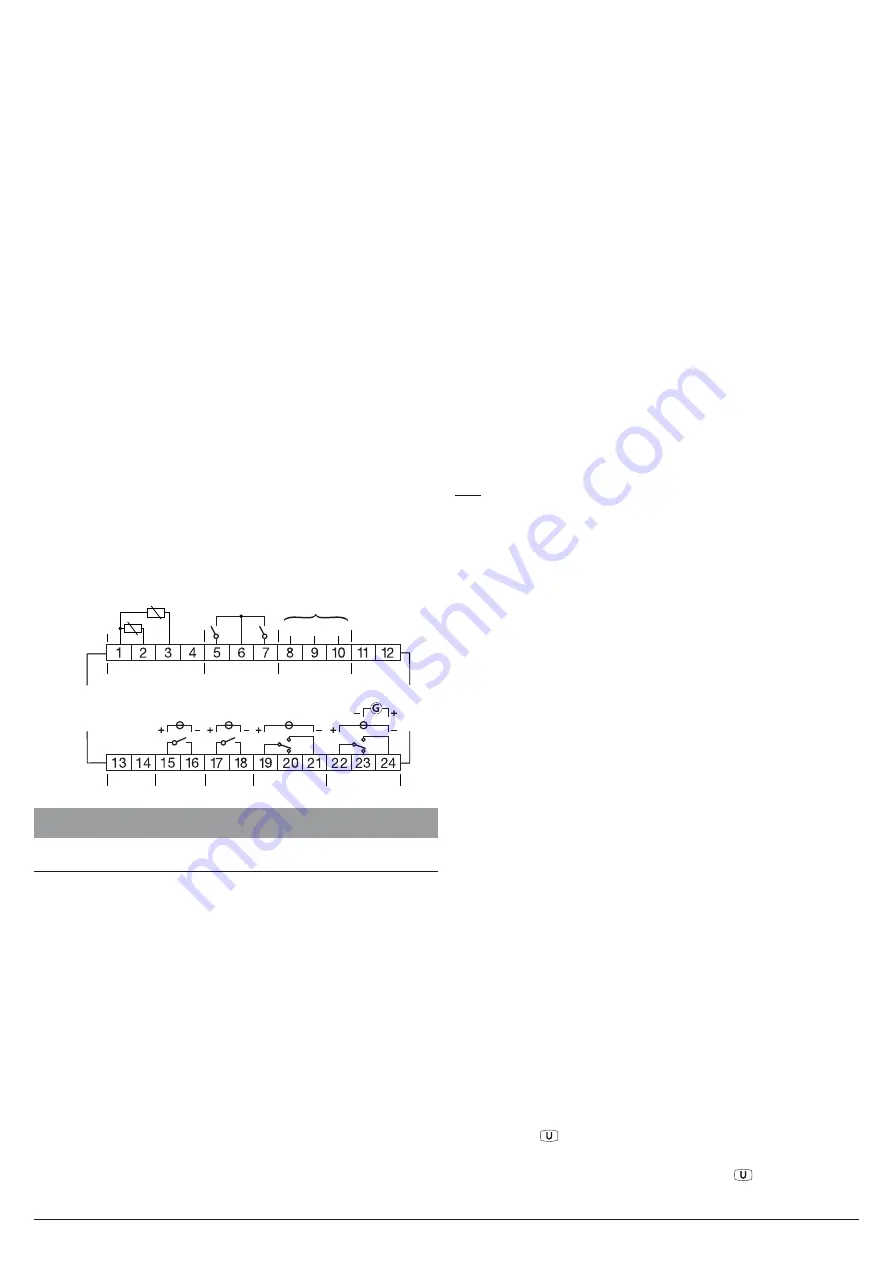

4.3.1

Electrical wiring diagram

OUT1

OUT2

OUT3

OUT4

Power

Supply

Analogue input

Digital input

Serial interface

SSR: Out 1, 2, 3, 4: 10mA/10VDC

Relays: Out-1, 2: 8A-AC1 (3A-AC3)/250VAC

Out-3, 4: 5A-AC1 (2A-AC3)/250VAC

Analog: Out 1: 0/4... 20mA or

0/2... 10VDC

Ptc/Ntc/

Pt1000

Pr1

Pr2

RS485

B GND A

DI2

DI1

5. FUNCTIONS

5.1 Measurement and display

All the parameters referring measurements are contained in

the group

]

InP

.

Using parameter

SEnS

, it is possible to select the probe input

type, which can be:

–

Thermistors PTC KTY81-121 (

Ptc

) or NTC 103AT-2 (

ntc

);

–

ResistanceThermometer Pt1000 (

Pt10

).

Notes: 1.

We recommend to switch ON and OFF the instru-

ment when these parameters are modified, in

order to obtain a correct measuring.

2.

When 2 temperature probes are connected to the

controller they must be of the same type.

Once the type of probe has been chosen, through the

Unit

parameter it is possible to choose the temperature meas-

urement unit (

°C

or

°F

) and through the

dP

parameter, the

desired temperature resolution (

0

=

1°

;

1

=

0.1°

).

If the

Pr2

probe is not used set parameter

Pr2

=

NO

to avoid

an error being indicated when the probe is not connected.

The instrument allows the measurement calibration, that can

be used to recalibrate the instrument according to application

needs. This can be done through parameters

OFS1

,

OFS2

and

rot

.

Setting

rot

=

1000

and

oFS

=

1

/

2

it is possible to set a

posi-

tive

or

negative

offset

that is simply

added

to the value read

by the probe before visualisation, which remains constant for

all the measurements.

If instead, it is desired that the

offset

set should

not be con-

stant

for

all measurements

, it is possible to execute a two

points calibration.

In this case, in order to decide the values to program on

OFSt

and

rot

, the following formulas must be applied:

rot

= (D2 - D1)/(M2 - M1)

oFS

= D2 - (

rot

x M2)

where:

M1

Measured value 1;

D1

Value to be displayed when the instrument measures M1;

M2

Measured value 2;

D2

Value to be displayed when the instrument measures M2;

Follows that the instrument will visualise:

DV

= MV x

rot

+

oFS

Where:

DV

= Displayed value

MV

= Measured value.

E.g.:

It is desired that the instrument displays the value ef-

fectively measured at 20° but that, at 100°, it displays 90° (10°

lower than the measured value).

Therefore: M1 = 20; D1 = 20; M2 = 100; D2 = 90

rot

= (90 - 20)/(100 - 20) =

0.875

oFS

= 90 - (0.875 x 100) =

2.5

With parameter

FiL

it is possible to program time constant

of the software filter for the input value measured, in order to

reduce noise sensitivity (increasing the reading time).

In case of measurement error, the instrument supplies the

power as programmed on parameter

OPE

. This power is calcu-

lated according to cycle time programmed for the PID control,

while for the ON/OFF control the cycle time is automatically

considered to be 20 s (e.g. In the event of probe error with ON/

OFF control and

oPE

=

50

, the control output will be activated

for 10 s, then deactivated for 10 s and so on until the measure-

ment error remains.).

With

InE

parameter it is possible to decide the input error con-

ditions that force the instrument in supplying the output power

programmed with

oPE

parameter.

The possible values for

InE

parameter are:

or

The condition occurs in case of overrange or probe break.

Ur

The condition occurs in case of underrange or probe break.

Our

The condition occurs in case of overrange, underrange

or probe break.

Through the

diSP

parameter of the

]

PAn

group it is possible to

decide which value the display must normally show; this could

be the

Pr1

probe reading (

Pr

1

), the

Pr2

probe reading (

Pr

2

),

the temperatures

Pr1 - Pr2

difference (

P1-2

), the power con-

trol (

Pou

), the

active Set Point

(

SP.F

), the

operative Set Point

when there are ramps activated

(

SP.o

) or the alarm limit

AL 1

,

AL 2

,

AL 3

(

AL1

,

AL2

,

AL3

).

Regardless of

diSP

parameter setting is possible to show the

variables

Pr1

,

Pr2

and

Pr1 - Pr2

in sequentially, pressing and

releasing the

key, the display alternately shows the code that

identifies the variable (

Pr

1

,

Pr

2

,

P1-2

), then and its value.

After 15 seconds following the last time the

key is pressed,

this type of display ends automatically.