Operating Instructions for Ascoline 700, AGH 2xx, 4xx, 6xx

ascobloc

Gastro-Gerätebau GmbH

D-01156 Dresden, Grüner Weg 29

Germany

Tel. +49 351 4533-0

Fax: +49 351 4537-339

E-mail:

AGH2XX.doc, Status: 23.05.2013

Subject to change without notice!

12

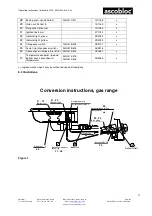

Düse

Überwurfschraube M10x1

Doppelkegelring RD4

Zündgasleitung

Luft- Regulierungsmutter

Hauptgasleitung

Überwurfmutter M16x1,5 SW 19

Doppelkegelring 10 mm

Zündbrenner

Backrohrbrenner

Thermoelement

Umstellanleitung Gas - Backrohr

SW 10

Düsenträger

H

G

D E F

D

E

F

Innendüse

SW 12

34

35

33

37

38

41

39

36

Figure 2

ZURÜCK nach rechts bis Rastpunkt Vollbrand 8 drehen,

Knebel leicht gedrückt nach rechts über Zündstellung

bis zur Aus- Stellung bringen

Betätigung Gas- Einstellglied Backrohr

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

8 7

6

5

4

3

2

1

Klappenöffnung anbrennen, ca. 10 Sekunden

stufenlos einstellbar

8

7

6

5

4

3

2 1

Stellung 1- ca.140°C

Stellung 2- ca.150°C

Stellung 3- ca.170°C

Stellung 4- ca.185°C

Stellung 5- ca.205°C

Stellung 6- ca.225°C

Stellung 7- ca.245°C

Stellung 8- ca.270°C

Aus- Stellung

Stellglied geschlossen

Zündstellung

Knebel tief drücken, ca. 30° nach links

in Zündstellung drehen, gedrückt halten und mit

Gasanzünder Zündbrennerflamme anbrennen, ca.

10 Sekunden gedrückt halten, danach ungedrückt auf

Vollbrand bis Anschlag nach links ca. 60° drehen

Vollbrandstellung

Knebel drücken, ca. 60° nach links

Kleinbrand stufenlos einstellbar

Kleinbrandstellung

Kleinbrand stufenlos einstellbar,

ZURÜCK nach rechts bis Rastpunkt Vollbrand drehen,

weiter zurück nach rechts bis Anschlag Zündstellung drehen,

Knebel leicht drücken und in Aus- Stellung bringen

Betätigung Gas- Einstellglied Herd

Aus- Stellung

Stellglied geschlossen

Zündstellung

Knebel drücken, ca. 30° nach links

in Zündstellung drehen, gedrückt halten und mit

Gasanzünder Zündbrennerflamme unterhalb der

gedrückt halten, danach leicht gedrückt auf

Vollbrand 8 nach links ca. 80° drehen

Vollbrandstellung 8

Knebel im Bereich von ca. 140° nach links

zwischen Stellung 8 bis 1 rasterartig

Kleinbrandstellung 1

Zwischenbereiche stufenlos einstellbar,

Figure 3

Conversion instructions, gas oven

Oven burner

Pilot burner

Nozzle holder

Inner nozzle

Main gas line

Olive, 10 mm

Union nut, M16x1.5 A/F 19

Thermocouple

Nozzle

Pilot gas line

Retaining screw M10x1

Air regulating nut

Olive, RD4

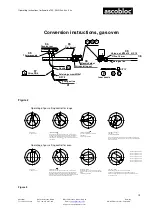

Operating of gas setting control for range

Off position

Actuator closed

Ignition position

Press in the knob deeply, turn approx. 30° to the left to the

ignition position, hold in the pressed-in position and light the

pilot flame with the gas igniter, keep pressed-in for 10 sec,

then release to the full flame

Turn to the left by about 60° to

the end stop

Full flame setting

Press knob, approx. 60° to the left

Low flame

Continuously adjustable

Low flame setting

Low flame

Continuously adjustable

Back to the right till the click-in position for full flame is reached, turn

further to right to the ignition position end stop, press knob lightly and

bring to off position

Operating of gas setting control for oven

Off position

Actuator closed

Ignition position

Press in the knob deeply, turn approx. 30° to the left to the

ignition position, hold in the pressed-in position and light the

pilot flame below the flap opening with the gas igniter, keep

pressed-in for 10 sec, then turn to the left by approx. 80°, while

keeping slightly depressed, to full flame position 8

Full flame position 8

Knob in the region of 140° to the left between

positions 8 and 1 can be continuously adjusted in

click-in

Continuously adjustable

Low flame setting 1

Intermediate ranges are continuously adjustable

Turn BACK to the right till it clicks in at full flame position 8,

depress knob slightly and turn to the right via the ignition position

to the OFF position

Position 1- approx. 140 °C

Position 2- approx. 150 °C

Position 3- approx. 170 °C

Position 4- approx. 185 °C

Position 5- approx. 205 °C

Position 6- approx. 225 °C

Position 7- approx. 245 °C

Position 8- approx. 270 °C

A/F 12

A/F 10