Issue 1324

507120-01

Page 14 of 18

Maintenance

•

Inspect air filters at least once a month and replace or

clean as required. Dirty filters are the most common

cause of inadequate heating or cooling performance.

•

Replace disposable filters. Cleanable filters can be

cleaned by soaking in mild detergent and rinsing with

cold water.

•

Install new/clean filters with the arrows on the side

pointing in the direction of airflow. Do not replace a

cleanable (high velocity) filter with a disposable (low

velocity) filter unless return air system is properly sized

for it.

•

If

water should start coming from the secondary drain

line, a problem exists which should be investigated and

corrected. Contact a qualified service technician.

Cabinet Insulation

Matte- or foil-faced insulation is installed in indoor equipment

to provide a barrier between outside air conditions

(surrounding ambient temperature and humidity) and the

varying conditions inside the unit.

If

the insulation

barrier is damaged (wet, ripped, torn or separated from the

cabinet walls), the surrounding ambient air will affect the

inside surface temperature of the cabinet. The temperature/

humidity difference between the inside and outside of the

cabinet can cause condensation on the inside or outside

of the cabinet which leads to sheet metal corrosion and

subsequently, component failure.

REPAIRING DAMAGED INSULATION

Areas of condensation on the cabinet surface are an

indication that the insulation is in need of repair.

If

the insulation in need of repair is otherwise in good

condition, the insulation should be cut in an X pattern, peeled

open, glued with an appropriate all-purpose glue and placed

back against the cabinet surface, being careful

to not overly compress the insulation so the insulation can

retain its original thickness. If

such repair is not possible,

replace the insulation. If

using foil-faced insulation, any cut,

tear, or separations in the insulation surface must be

taped with a similar foil-faced tape.

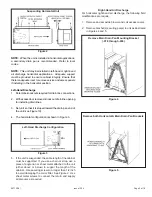

Figure 13

Repairing Insulation

Do not operate system without a filter. A filter is

required to protect the coil, blower, and internal parts

from excessive dirt and dust. The filter is placed in the

return duct by the installer.

IMPORTANT

DAMAGED INSULATION MUST BE REPAIRED OR

REPLACED

before the unit is put back into operation.

Insulation loses its insulating value when wet, damaged,

separated or torn.

IMPORTANT

Содержание BCE3M 18

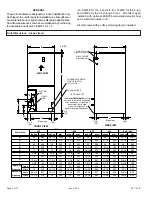

Страница 11: ...Page 11 of 18 Issue 1324 507120 01 Figure 12 Low Voltage Connections 3 Speed PSC Motor...

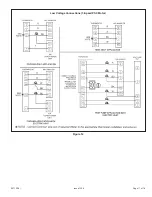

Страница 15: ...Page 15 of 18 Issue 1324 507120 01 Start Up and Performance Checklist Horizontal Configuration Figure 14...

Страница 16: ...Issue 1324 507120 01 Page 16 of 18 Figure 15 Start Up and Performance Checklist Upflow Configuration...