Issue 1324

507120-01

Page 10 of 18

Make sure the liquid line and suction line entry points are

sealed with either Armaflex material or with Permagum.

Permagum may also be used to seal around the main and

auxiliary drains and around open areas of electrical inlets.

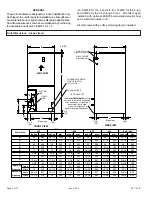

Electrical Connections

Electric shock hazard!

- Disconnect all

power supplies before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

•

All field wiring must be done in accordance with National

Electrical Code, applicable requirements of UL and local

codes, where applicable.

•

Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to

the air handler rating plate for maximum over-current

protection, minimum circuit ampacity, as well as

operating voltage.

•

The power supply must be sized and protected

according to the specifications supplied on the product.

•

This air handler is factory-configured for 240 volt, single

phase, 60 cycles. For 208-volt applications, see “208

Volt Conversion” later in this section.

•

For optional field-installed electric heat applications,

refer to the instructions provided with the accessory for

proper installation.

1. Disconnect all power supplies.

2. Remove the air handler access panel.

3. Route the field supply wires to the air handler electrical

connection box.

4. Use UL-listed wire nuts to connect the field supply

conductors to the unit black and yellow leads, and the

ground wire to ground terminal marked “GND.”

5. Replace the air handler access panel.

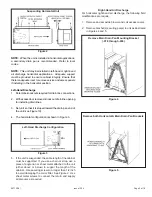

208 VOLT CONVERSION

1. Disconnect all power supplies.

2. Remove the air handler access panel.

3. Using the wiring diagram located on the unit access

panel as a reference, move the 2 connected black

transformer leads from the 240 volt terminal on the

transformer to the 208 volt terminal on the transformer.

Making Electrical Connections

Figure 11

WARNING

ELECTRIC SHOCK HAZARD

Can cause injury or death.

Foil-faced insulation has conductive characteristics

similar to metal. Be sure there are no electrical

connections within a 1/2” of the insulation. If the foil-

faced insulation comes in contact with electrical voltage,

the foil could provide a path for current to pass through

to the outer metal cabinet. While the current produced

may not be enough to trip existing electrical safety

devices (e .g. fuses or circuit breakers), the current can

be enough to cause an electric shock hazard that could

cause person al injury or death.

USE COPPER CONDUCTORS ONLY!

WARNING

Electrically ground air handler. Connect

ground wire to ground terminal marked

“GND”.

Failure to do so can result in death or

electrical shock.

WARNING

Содержание BCE3M 18

Страница 11: ...Page 11 of 18 Issue 1324 507120 01 Figure 12 Low Voltage Connections 3 Speed PSC Motor...

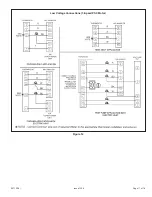

Страница 15: ...Page 15 of 18 Issue 1324 507120 01 Start Up and Performance Checklist Horizontal Configuration Figure 14...

Страница 16: ...Issue 1324 507120 01 Page 16 of 18 Figure 15 Start Up and Performance Checklist Upflow Configuration...