Issue 1324

507120-01

Page 4 of 18

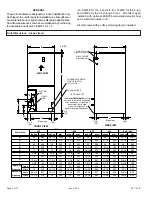

Installation Clearances

NON-DUCTED RETURN CLOSET INSTALLATION

The air handler can be installed in a closet with a false bot-

tom to form a return air plenum. It may also be installed with

a return air plenum under the air handler.

Louvers or return air grilles are field supplied. Local codes

may limit application of systems without a ducted return to

single story buildings.

When these unit are installed in a closet with a louvered

return opening, the minimum open area for the louvers will

be:

•

320 square inches for -018 and -024 models;

•

360 square inches for -030 and -036 models;

•

450 square inches for -042 thru -060 models.

If the free area is not known, assume a 25% free area for

wood or a 75% free area for metal louvers or grilles. Using

the louver dimensions and the 25% or 75% assumption,

determine if the open area meets the minimum open area

listed above.

If a return air plenum is used, the return air grille should be

immediately in front of the opening in the plenum to allow

for the free flow of return air. When not installed in front of

the opening, there must be adequate clearance around the

air handler to allow for the free flow of return air.

These

units are factory assembled and configured for

installation in upflow or horizontal left hand air discharge

applications.

Each unit consists of a blower assembly, refrigerant coil, and

controls, in an insulated galvanized steel factory finished

enclosure. Knockouts are provided for electrical wiring

entrance.

For ease in installation, it is best to make any necessary coil

configuration changes before setting air handler in place.

For all performance testing, units must be tested in the

upflow orientation with the horizontal drain pan removed.

Refrigerant Metering Device

These units are equipped with a orifice metering device.

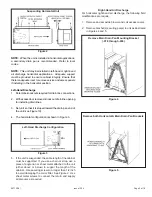

Upflow Application

1. The air handler must be supported on the bottom only

and set on solid floor or field supplied support frame.

Securely attach the air handler to the floor or support

frame.

2. If installing a unit in an upflow application, remove the

horizontal drain pan.

IMPORTANT:

The horizontal drain pan is not required

in upflow air discharge installations; its removal provides

the best efficiency and air flow.

3. Place the unit in the desired location and level it. Connect

return and supply air plenums as required using sheet

metal screws.

4. Install units that have no return air plenum on a stand

that is at least 14” from the floor. This will allow proper

air return.

INSTALLATION

General Information

Horizontal Applications

Figure 1

Upflow Configuration

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a qualified installer or service agency.

WARNING

When removing the coil, there is possible danger of

equipment damage and personal injury. Be careful

when removing the coil assembly from a unit installed

in right- or left-hand applications. The coil may tip into

the drain pan once it is clear of the cabinet. Support the

coil when removing it.

IMPORTANT

Содержание BCE3M 18

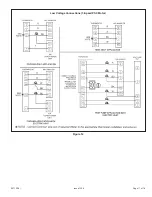

Страница 11: ...Page 11 of 18 Issue 1324 507120 01 Figure 12 Low Voltage Connections 3 Speed PSC Motor...

Страница 15: ...Page 15 of 18 Issue 1324 507120 01 Start Up and Performance Checklist Horizontal Configuration Figure 14...

Страница 16: ...Issue 1324 507120 01 Page 16 of 18 Figure 15 Start Up and Performance Checklist Upflow Configuration...