ARKEL Elektrik Elektronik Ltd.

Ş

ti. www.arkel.com.tr

08.2012

ADrive

75

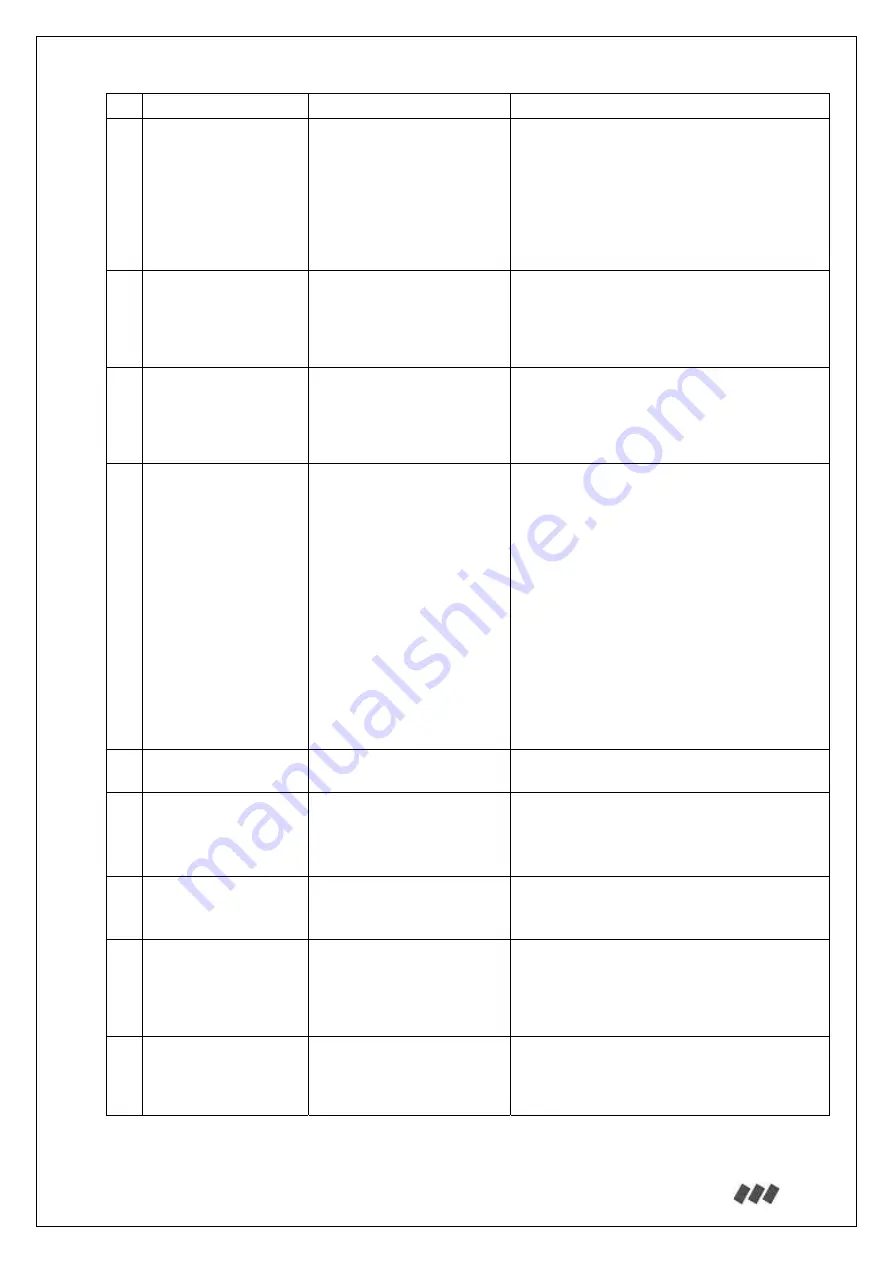

No

Trip Meaning

Probable Causes / Corrective Actions

07 POWER

FAILURE

The main supply voltage L1,

L2, L3 oscillates unusually.

1- The main supply voltage is too low.

2- An open-phase error occurred at the input

power supply.

3- A momentary power loss occurred.

4- The wiring terminals for the input power

supply are loose.

5- The voltage fluctuations in the input power

supply are too large.

08

AUTO TUNE FAILS

A fault occurred during

autotuning in open loop mode.

Autotune operation cannot be

completed.

1- Check motor connection. Motor connection

may not be done properly.

2- Motor contactor may not be switching. Be sure

that the motor contactor closes when inverter is

running.

09 OVER

SPEED

The speed read from encoder

is too high.

1- Motor speed may be higher than the reference

speed. Check motor setup in the menu.

2- Compare the pulse number setting in the menu

“Motor Setup - Encoder Resolution” with the

encoder pulses and correct if necessary.

10 BAD

ENCODER

SGNL

The encoder signals oscillates

unusually.

1- Check encoder connection and encoder

voltage.

2- Check the connection between encoder and

motor.

3- If the encoder cable is not shielded, use a

shielded cable.

4- If the motor cable is not shielded, use a

shielded cable.

5- Encoder cable may be placed too close to

motor cable. Motor cable and encoder cable

channels should be separate. Minimum distance

between cables should be at least 10cm.

6- Encoder may be grounded at both the motor

side and inverter side. If the encoder is grounded

at motor side, disconnect the grounding at inverter

side.

12 CONTACTOR

DROPPED

The main contactor(s) dropped

out while driver is running.

Check the supply circuit of the main contactors’

coils.

13 NO

CONTACTOR

SGN

No contactor picked up signal

is detected in 5 seconds after a

speed signal and direction

signal are detected.

Check the auxiliary contacts of the main

contactors in drive enable (EN) signal circuit.

14

LOW MOT.

CURRENT

No current can be delivered to

motor coils.

1- Motor wiring may not be connected properly.

Check broken or disconnected wiring.

2- Check the connection of main contactors.

15 WRONG

DIRECTION

Lift is not running in required

direction. Running direction

read from encoder is different

from the direction inverter

commands.

1- U, V, W phases of motor reversed. Check

motor connection.

2- Phase of encoder reversed.

16 UNBALLANCED

CUR.

Unballanced current at U, V,

W motor outputs. Over-

current at one or two of motor

outputs.

1- Contacts of main contactor may not conduct.

Check the connection of main contactors.

2- A faulty motor windings.