35

settings - adjustment - problem identifi cation menus

Accessing the settings - adjustment - problem identifi cation

menus

The boiler can be used to manage the heating and domestic hot

water production system in its entirety.

Navigation within the menus enables the boiler

connected peripheral units to be customised, optimising

operation for maximum comfort and maximum saving. It also

provides important information relating to the effi

cient operation

of the boiler.

The available menus are as follows:

2

Boiler Parameter

2

1

Service code

(access reserved for qualifi ed engineers)

2

2

General setting

2

3

C.H. Parameters - Part 1

2

4

C.H. Parameters - Part 1

2

5

Domestic Hot Water (Combi only)

2

9

Menu 2 Reset to factory setting

3

Solar & Storage

3

0

General setting

3

1

Service code

(access reserved for qualifi ed engineers)

3

2

Special setting

4

Zone 1 Parameters

4

0

Set-point Zone1

4

1

Service code

(access reserved for qualifi ed engineers)

4

2

Zone 1 Setting

4

3

Diagnostics

4

4

Zone device mangement

5

Zone 2 Parameters

5

0

Set-point Zone2

5

1

Service code

(access reserved for qualifi ed engineers)

5

2

Zone 2 Setting

5

3

Diagnostics

5

4

Zone device mangement

5

5

Multizone

7

Test & Utilities

8

Service Parameter

8

1

Service code

(access reserved for qualifi ed engineers)

8

2

Boiler

8

3

Boiler Temperature

8

4

Solar & Storage

8

5

Service

8

6

Statistics

8

7

NOT ACTIVE

8

8

Error History

The parameters relating to each individual menu are listed in the

following pages.

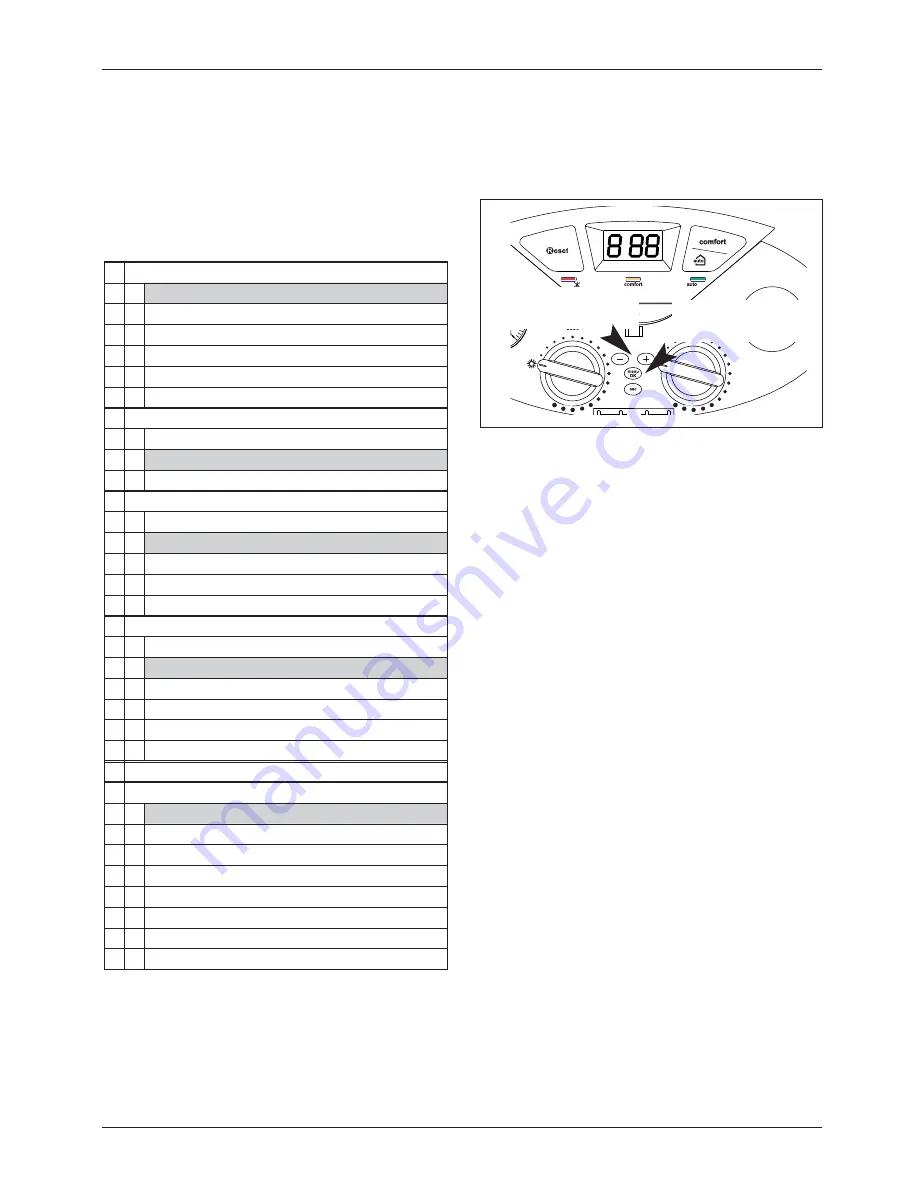

The various parameters can be accessed and modifi ed using th M

ENU

/

O

K

button and the +/- buttons (see fi g. below). The code of the menus

and of each individual parameter will be shown on the display.

The information relating to the menus and the individual parameters

are indicated on the display.

To access Menu 2, open the cover and proceed as follows:

1. Press the M

ENU

/O

K

button; the fi rst fi gure

0

0

00

will fl ash on the

display.

2. Press the “+” button to select menu “

2

2

00”

3. Press the M

ENU

/O

K

button; the second fi gur on the display will

fl ash and the access code “

21

1

0

” will be requested.

Caution!

The menus reserved for qualifi ed technicians may only

be accessed after setting the access code.

4. Press the M

ENU

/O

K

button;

222

will appear on the display unit.

5. Press the “+” button to select code

234

234

.

6. Press the M

ENU

/O

K

button to select the sub menu; the second

fi gure “

22

2

0

” will fl ash.

7. Press the “+” button to select the sub menu, for example: “

23

3

0

”.

8. Press the M

ENU

/O

K

button to access the sub menu parameters; the

third fi gure “

230

0

”

will fl ash.

9. Press the +/- buttons to select the parameter; then press the

Menu/Ok button.

10. Press the “+” or “-” button to access the parameter; the display will

indicate the value, e.g “

76

”.

Note:

The parameter value will be displayed for 20 seconds, then

will begin to fl ash in alternation with the parameter, e.g. “

70

70

>

231

231

”.

11. Press the “+” or “-” button to select the new value, e.g. “

75

”.

12. Press M

ENU

/O

K

to save the change or press E

SC

to exit without

saving.

To exit, press the ESC button until the normal display screen is

restored.

P

ROGRAMMING

BUTTON

M

ENU

/O

K

BUTTON

Содержание Clas 24 FF

Страница 23: ...23 installation WIRING DIAGRAM FOR CONNECTION TO AN OPEN VENTED CYLINDER ...

Страница 24: ...24 installation WIRING DIAGRAM FOR CONNECTION TO AN MTS UNVENTED CYLINDER ...

Страница 57: ...57 maintenance guide 4 BURNER UNIT Burner unit ...

Страница 64: ......

Страница 67: ......