4

Technical Installation Instructions and User Guide

GB

Technical Installation Instructions and User Guide

Safety assembly

The.unit.must.be.installed.with.a.safety.assembly.that.meets.current.national.and.EU.standards,.connected.to.the.cold.water.inlet.tube.and.

suitable.for.the.maximum.working.pressure.indicated.on.the.technical.label.

It.is.advisable.to.use.a.safety.assembly.with.a.membrane.

The.safety.assembly.1’’.must.be.installed.as.close.as.possible.to.the.cold.water.inlet.and.the.water.flow.must.not.be.obstructed.by.other.acces-

sories.

If,.for.technical.reasons,.the.safety.assembly.cannot.be.installed.with.a.direct.link.to.the.cold.water.inlet,.a.rigid.link.with.the.same.dimensions.

as.the.1’’.cold.water.inlet.must.be.used.

In.any.case,.the.link.must.be.made.using.a.material.that.is.able.to.withstand.the.temperatures.and.pressures.indicated.on.the.technical.label.

The.outlet.for.the.safety.assembly.should.never.be.obstructed.and.should.be.linked.to.vertical.evacuation.tubes.with.a.diameter.at.least.as.

large.as.that.of.the.unit's.connections.

It.is.recommended.that.the.safety.assembly.be.installed.as.low.down.as.possible.so.that.the.unit.can.be.drained.sufficiently.

If.the.supply.pressure.is.greater.than.4/5.bar,.a.pressure.reducer.must.be.installed.upstream.of.the.safety.assembly.

It.is.recommended.that.a.stop.valve.be.positioned.upstream.of.the.safety.assembly.

Always use new connection piping to make connections to a water supply network, never install used pipes. These pipes must also conform to the EN

61770 standard.

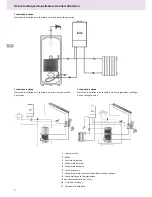

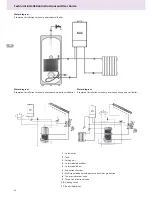

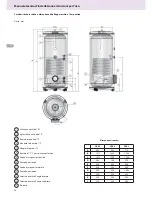

1

3

2

4

1

5

7

3

6

Key :

1

..Stop.valve

2

..Pressure.regulator

3

..Non-return.valve

4

..Pressure.gauge.connection.with.pressure.gauge

5

..Safety.valve

6

..Drainage.valve

7

..Deaerator