8

3. GASIFICATION

TECHNOLOGY

Boiler ASPIRO operation is based upon the gasification technology applied to wood. The solid fuel, stored in

the upper collection chamber in contact with hot ashes in its bottom part, on the burner’s grate, releases

combustible gazes which may be fired when mixed with the main air stream. This flammable compound is

sucked through the slot existing in the bottom part of the wood collection chamber, where it will light

producing the characteristic

“reverse flame”.

The gasification principle, not allowing wood to burn directly as in any other classic arrangement but using

instead the gazes released under high temperature conditions, allows a complete burning of the fuel which

permits to get high thermal yield and a very low level of harmful emissions in the smoke released outside.

The boiler ASPIRO has been designed to limit to the maximum possible level the harmful action of the acid

condensate. The burner chamber has a 8 mm thickness walls and has no welding in its upper part;

furthermore, the rear and front walls are protected by a refractory cement layer and they are not in touch with

water (dry walls).

4.

MAIN BOILER COMPONENTS

4.1. WOOD

COLLECTION

CHAMBER

It is the

fuel "tank" of the boiler. In this chamber, located in the boiler upper part, the wood logs are charged

after being succesfully performed the ignition procedure, getting a first layer of hot ashes.

4.2. MAIN BURNER REFRACTORY CEMENT FRAME AND BARS

In the middle part of the boiler, between the fuel chamber and the bottom part where the heat exchange

takes place, is located the burner, built with a special designed refractory cement frame with a slot in its

central part and a grate. The grate is formed by single elements (the “bars”), realized in chrome cast iron,

which support the ashes while letting the released gazes passing through downward.

4.3. HEAT EXCHANGE AREA AND CATALYST ELEMENTS

The gazes released by wood, after being passed through the cast iron bars, light producing a bluish vertical

reverse flame which touches a special shaped chrome cast iron cylinder called "the catalyst".

The flame, passing through this cast iron element which reaches a very high temperature, will have

completely burnt the main part of its residual carbon particles which were not burnt before. The combustion

gazes, flowing through the heat exchanging zone, warm up the water.

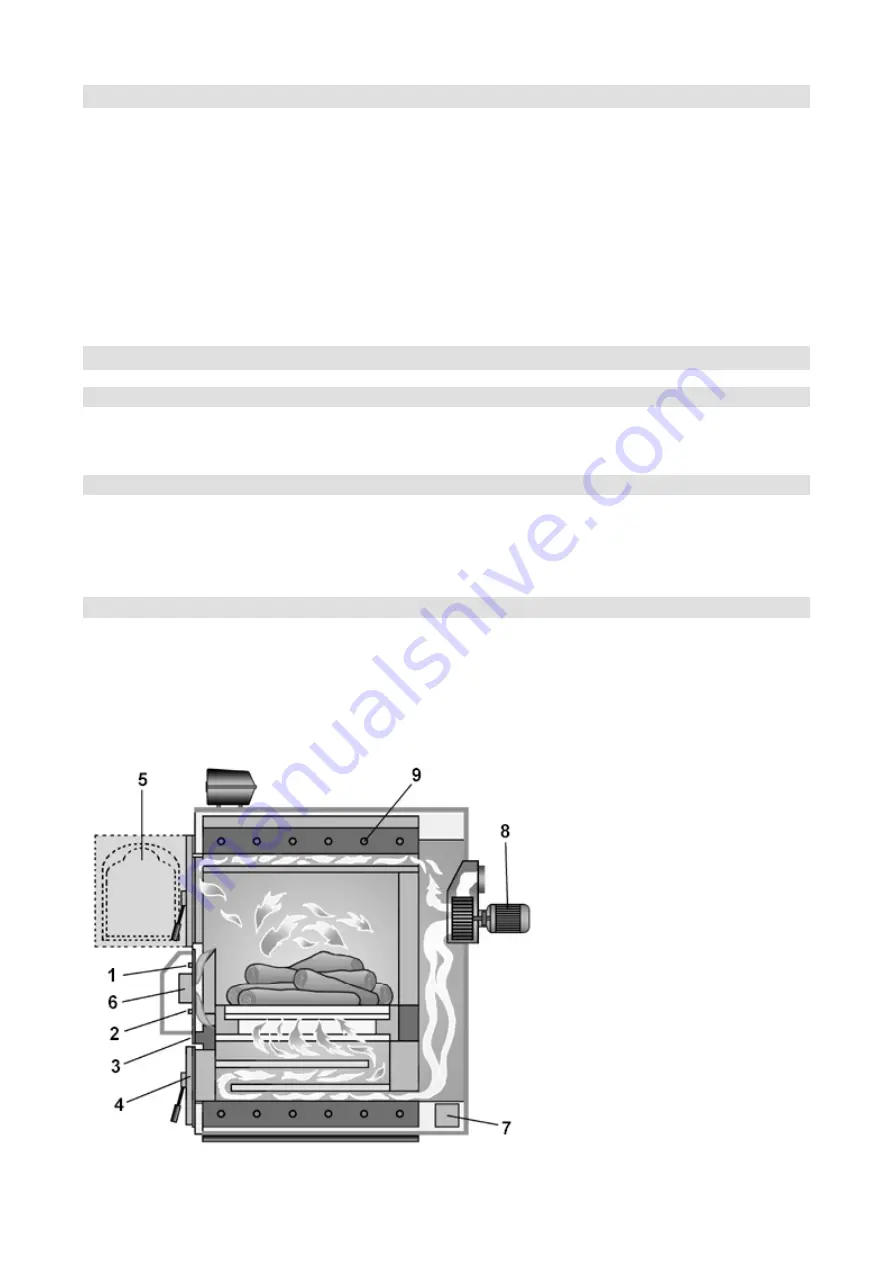

Key:

1

Primary air stream adjusting

2

Secondary air stream adjusting

3

Flame control bull's eye

4

Bottom door (combustion

chamber)

5

Upper door (wood chamber)

6

Combustion air modulator

7

Anti deflagration door

8 Fan

motor

9

Hot sanitary water heat

exchanger (SA versions only)

Содержание ASPIRO A 29 R/SA

Страница 1: ...ASPIRO Installation Operation Maintenance www arcacaldaie com ...

Страница 2: ...2 ...