36

The fan does not stop and the

boiler does not reach the operation

temperature.

a) Plugged

boiler.

b) Pumps not connected or

blocked.

c) Wood

loaded

without

respecting the outlined

prescriptions.

d) Boiler not correctly

dimensioned to the real heat

needings.

e) See

16,1

a) Clean the boiler in all its parts.

b) Connect the pumps to the

control board.

c) When loading the wood, be

careful not to leave empty

spaces.

d) Progressively open one after

another the existing system

zones.

For any problem we recommend having the boiler inspected by an authorized assistance center.

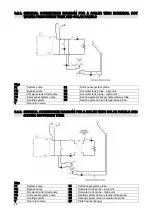

15. OPERATING

ABNORMALITIES

15.1. ACOUSTIC WARNING

If an excessive temperature is reached, the boiler will emit an acoustic warning.

This value is set by parameter #3 which is set by default at 88 °C (page 19, page 24, page 28)

In some real situations, the operating temperature may require being set higher than standard, i.e. if the

heating system includes electroventilating unit heaters far from the boiler installation place, besides

parameter #1 setting (working temperature 80 °C).

In this case the overheat acoustic warning could trip frequently.

In such a situation it is better to increase parameter #3 (Maximum temperature in thermal inertial mode), up

to a maximum value of 95°C.

If the acoustic warning trips without boiler temperature increasing, it may be caused by other system

abnormalities, such as too much flue draft, wood loading door open, heating system pump or bypass pump

stuck or blocked, faulty electronic board.

Another tip: if a greater working temperature is required than the preset value of 80°C, increase the

parameter #3 (Maximum temperature in thermal inertial mode).

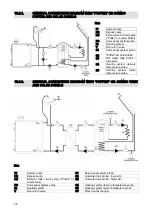

16. GENERAL TECHNICAL TIPS

16.1. SETTINGS AND HIGHEST PERMITTED TEMPERATURES

High power boilers are often used to heat industrial plants in the wood processing sector.

In such situations, the process waste is used to fuel the boiler.

Often, waste materials are very dry and contain synthetic resins and paints which should not be used as fuel.

Thus their thermal power is very high, and consequently the boiler output power as well as the smoke

exhaust temperature increase significantly.

WARNING!: if the smoke exhaust temperature goes beyond 200°C, drafting fan motor problems

may occur (the bearings lubricating grease dries), the burner grate bar cast iron elements may

quickly wear out, the same thing happens with the catalyst elements and so on.

Therefore is strongly advisable to monitor the smoke temperature, proportionally reducing the combustion air

supply and to mix with the dry wood waste other less dry wood with a lower specific thermal power.

For a proper system operation the smoke exhaust temperature must be in the range 160°C - 200°C.

If it is lower, condensation and corrosion problems may appear.

If it is higher, fan problems may occur and the burner bar and the catalyst elements may wear out quickly.

Obviously, a proper boiler setting “on site” is required for the many specific thermal power differences among

the various wood types which can be used.

Содержание ASPIRO A 29 R/SA

Страница 1: ...ASPIRO Installation Operation Maintenance www arcacaldaie com ...

Страница 2: ...2 ...