2

TABLE OF CONTENTS

ITEM PAGE

ITEM

PAGE

Safety Precautions ............................................ 3

Cleaning/Maintenance ............................................ 9

General Installation Instructions ........................ 4

Service/Repair ........................................................ 9

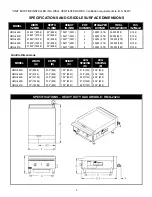

Specifications & Dimensions ............................. 5

Troubleshooting Guide ......................................... 10

Conversion ........................................................ 6

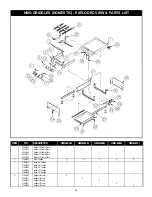

Replacement Parts Lists & Exploded Views ......... 11

Lighting Instructions .......................................... 7

Warranty ............................................................... 17

Operating Instructions ....................................... 8

LOCATION OF DATA PLATE

The data plate is located on the right side panel.

CAUTION:

These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment, make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

anyone using the equipment will use it correctly and not injure themselves or harm the

equipment.

WARNING:

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

WARNING:

For your safety do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Keep the area free and clear of

combustibles. (See ANZI Z83. 14B, 1991).

NOTICE:

Instructions to be followed if anyone smells gas should be posted in a prominent

place. These may be obtained from the gas supplier.

GAS PRESSURE

The appliance and it’s individual shutoff valve (to be supplied by user) must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½ psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing it’s individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psi

(3.45 kPa).

WARNING:

A factory authorized agent should handle all maintenance and repair. Before

doing any maintenance or repair, contact APW Wyott.

Congratulations on your purchase of APW Wyott commercial cooking or refrigeration equipment. APW Wyott

takes pride in the design and quality of our products. When used as intended and with proper care and

maintenance, you will experience years of reliable operation from this equipment. To ensure best results, it is

important that you read and follow the instructions in this manual carefully.

Содержание HMG-2424i

Страница 16: ...16 NOTES...

Страница 17: ...17 NOTES...