29

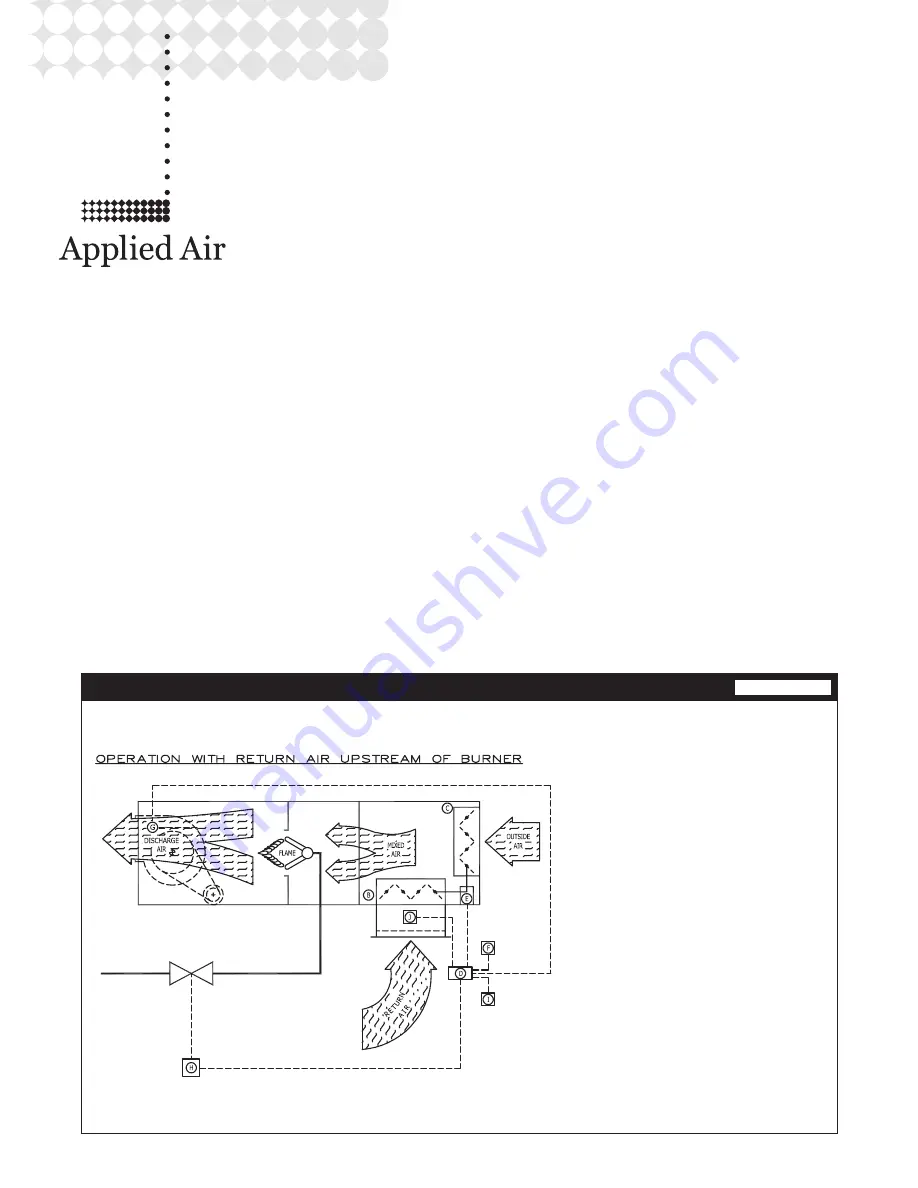

Sequence of Operation – Return Air Units

Signal from remote control I to AdaptAire

Controller D, sets operational parameters

for dampers B and C, and burner. Damper

operation can be manual, building pres-

sure or mixed air temperature.

Return air dampers B, and outside air

dampers C, are interlocked to move

together. As one opens, the other closes.

As the return air dampers open, allowing

more return air to enter the unit, the out-

side air dampers move toward the closed

position, decreasing the amount of outside

air. Pressure sensor and flow station J,

senses change in return airflow and signals

AdaptAire Controller D.

Modulating gas valve H, regulates gas

supply in response to signal from AdaptAire

Controller D. AdaptAire Controller D, var-

ies signal based on input from room tem-

perature sensor F, discharge temperature

sensor G, and airflow sensor J. Gas valve H

can provide approximately 4% to 100% of

rated burner capacity.

P000621

Guide Specification – Mixing Dampers With

Return Air Flow Station

Unit(s) shall have outside air and return

air dampers with modulating actuator

controlled by AdaptAire DDC control

system (Patent #7,059,536). The AdaptAire

DDC control system shall have capability

to digitally control the outside air quantity

from a nominal minimum of 20% to 100%

with integrated gas valve control at all room

concentrations of CO2.

The return air inlet shall include a self-

calibrating flow measuring station with a

grid of velocity pressure probes with spacing

no greater than 12” over the entire face of

the return air opening and sampled every

second. Samples are averaged to provide

smooth, accurate data that is delivered to

the AdaptAire DDC control system every

second. The DDC control system shall

be capable of electronically displaying

the return air/outside air ratio within 5%

accuracy at all damper positions.

The AdaptAire DDC control system shall be

capable of controlling mixing dampers in:

(Choose One)

Manual Mode:

The “Manual” mode allows

manual positioning of the outside air (O.A.)

damper and return air (R.A.) damper by

changing the damper position setpoint.

Mixed Air Temperature Mode:

The “Mixed

Air Temperature” mode shall provide auto-

matic control of the mixed air temperature by

modulating the outside air (O.A.) damper and

return air (R.A.) damper to maintain the mixed

air temperature setpoint.

Building Pressure Mode:

The “Building Pres-

sure” mode shall provide automatic building

pressure control by modulating the outside air

(O.A.) damper and return air (R.A.) damper to

maintain the indoor building pressure setpoint.

As the building pressure decreases below the

setpoint more outside air will be introduced.

Содержание DFL 035

Страница 23: ...23 Gas Piping Layout Schematic Component Diagrams C000504 ...

Страница 31: ...31 ...