29

V

.

TEST RUN

1. Preparation before Synchronous adjustment

a. Fill the reservoir with hydraulic oil. In consideration of power unit’s durability and

keep the equipment running in the perfect condition,

please use Hydraulic Oil

46#.

b. Turn on the power after connecting oil system correctly. Press the button

Up

, and

check the rotated direction of the motor (This is right if lift is upward, otherwise, it is

wrong direction of the motor). Shut off power and exchange the phase connection if

the direction is wrong.

c. Lower the platforms to the lowest position.

2. Synchronous adjustment

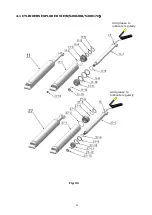

a. Turn the handles of the shutoff valves to the position as

Fig. 35

(Normal working

position), push

UP

button to start filling oil in the cylinder, until the machine starts

to lift. at this time push

Down

and

Pass

button about 5 seconds while hearing the

buzzer sound and the sounds of inside air coming out from oil tank . Repeat the

above steps 2-3 times until the inside air are all come out.

b. Tap

UP

button, until the platform just be lifted up.

c. Turn the handle of shutoff valves to the position as

Fig.36.

push

UP

button, check If

PI ,PII platform at the same time means the machine is synchronization. If still not,

repeat b steps until the both side of platform are synchronization.

d. After PI,PII platform are synchronization, operating the lift up and down.

3. Test run

Check and adjust the limit switch, the hose and fitting connection, and do test run.

The lift must be tested run and checked carefully before in use.

Fig. 35

Fig. 36

Normal Working Position

Oil Filling Position