14

American Dryer Corp.

113345-9

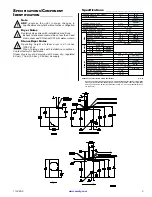

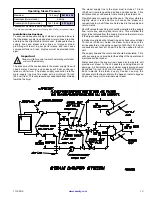

Steam Damper Air Piston (Flow Control) Operation

Adjustment

Although the steam damper operation was tested and

adjusted prior to shipping at 80 psi (5.52 bar), steam damper

operation must be checked before the dryer is put into

operation. Refer to the previous page for instructions to check

steam damper operation. If steam damper adjustment is

necessary, locate the flow control valve and make the

necessary adjustments as noted below.

COMPRESSED

AIR SUPPLY

AIR PRESSURE

Normal

80 psi

5.51 bar

Minimum Supply

70 psi

4.82 bar

Maximum Supply

90 psi

6.21 bar

!

Steam Damper Air System Connections

The dryer is manufactured with a pneumatic (piston) damper

system, which requires an external supply of compressed

air. The air connection is made to the steam damper solenoid

valve, which is located at the rear inner top area of the dryer

just in front of the electric service relay box.

Air Requirements

Shaded areas are stated in metric equivalents

Air Connection

Air connection to system — 1/8” N.P.T.

No air regulator or filtration is provided with the dryer. External

regulation/filtration of 80 psi (5.52 bar) must be provided. It is

suggested that a regulator/filter gauge arrangement be

added to the compressed air line just before the dryer

connection. This is necessary to ensure that correct and

clean air pressure is achieved.

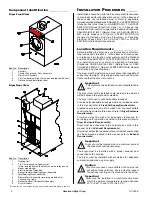

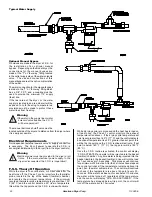

Steam System Operation

The steam damper shown in Diagram 1, allows the coil to

stay constantly charged eliminating repeated expansion and

contraction. When the damper is opened, the air immediately

passes through the already hot coil, providing instant heat to

start the drying process. When the damper is closed, ambient

air is drawn directly into the basket (tumbler), allowing a rapid

cool down (Diagram 2).

Diagram 1

shows the damper in the heating (open) mode,

allowing heat into the basket (tumbler).

Diagram 2

shows the damper in the cool down (closed)

mode, pulling ambient air directly into the basket (tumbler)

without passing through the coils.

Note

With the dryer off or with no air supply, the steam

damper is in cool down mode as shown in Diagram

2.

Содержание ML-55 Phase 7

Страница 26: ...ADC 113345 9 12 01 04 6 ...