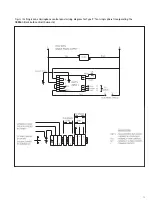

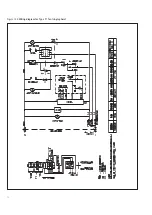

Figure 11 Logic sequence for Herringbone control panel

6 Control system

The control system must be installed in

accordance with the design specification.

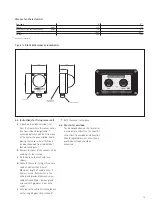

6.1 Control panel design

Ambi-Rad control panels are available

either as standard units to control

single or multiple zones of heaters

utilising the Ambi-Rad black bulb

radiant thermostat. Special control

functions are available on request.

Herringbone control panels use the

logic in figure 11 to operate in a safe

and satisfactory manner.

6.2 Installation of control panel

To install the Ambi-Rad control panel

remove the plastic plugs from the four

9mm diameter holes in the back of the

control box. Using these holes fix the

box in a convenient position to a

suitable plugged wall or solid structure

with No. 10 gauge wood screws or

6mm diameter bolts or set screws.

Access to the holes may be gained from

the inside of the box without the

necessity of removing the wiring

chassis. Make the electrical connections

in accordance with figure 12a or 12b

and cut holes in the removable gland

plate provided in the box. Conduit or

strain relief glands should be used.

Power onto panel

Mode switch in off position

Mode switch in auto position

Mode switch in constant position

(one or all zones)

No heaters on

Time clock off

Time clock on

Break contacts 8 & 9 on

Make contacts 8 & 9 on

black bulb controller

black bulb controller (via relay or

time clock contacts for each zone

Control on night temperature

Control on day

setting for frost protection

temperature setting

Call for heat by black bulb controller

controlling each zone or all heaters

Delay start of Herringbone fan for 30 seconds

to ensure vacuum switch on heaters is

broken (only required for 2 zones or

more on one fan)

Switch on the power suuply to the

Herringbone fan and power supply to

heaters simultaneous

Individual heater vacuum switch senses combustion vacuum

Individual heaters start ignition sequences

Zone control switches off

Other zones carry on firing (if fitted)

Zone control calls for heat

Power off to all heaters or zones

and to stop Herringbone fan

(Possible

alternative

control

function to

override

temperature

controller)

11

Содержание Herringbone HB

Страница 1: ...HERRINGBONE HB COMBINED FLUE SYSTEM...

Страница 14: ...Figure 12b Wiring diagram for Type 0 fan single phase 13...