3.1 Method of jointing aluminium tube

Using the applicator gun exude 4mm

diameter bead of high temperature

silicon jointing compound externally

round the end of the fitting and

internally round the end of the tube.

(See figure 2)

Enter the fitting into the tube using

a slight rotating movement to spread

the jointing compound uniformly

until a penetration of 75mm (3in)

is achieved.

Note

The silicon jointing compound

remains workable after application

for only 5 minutes.

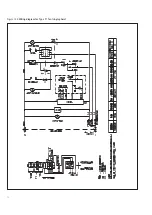

Figure 1 Typical Herringbone heating arrangement using

AR

22

HB

and

HB

22

AR

heaters

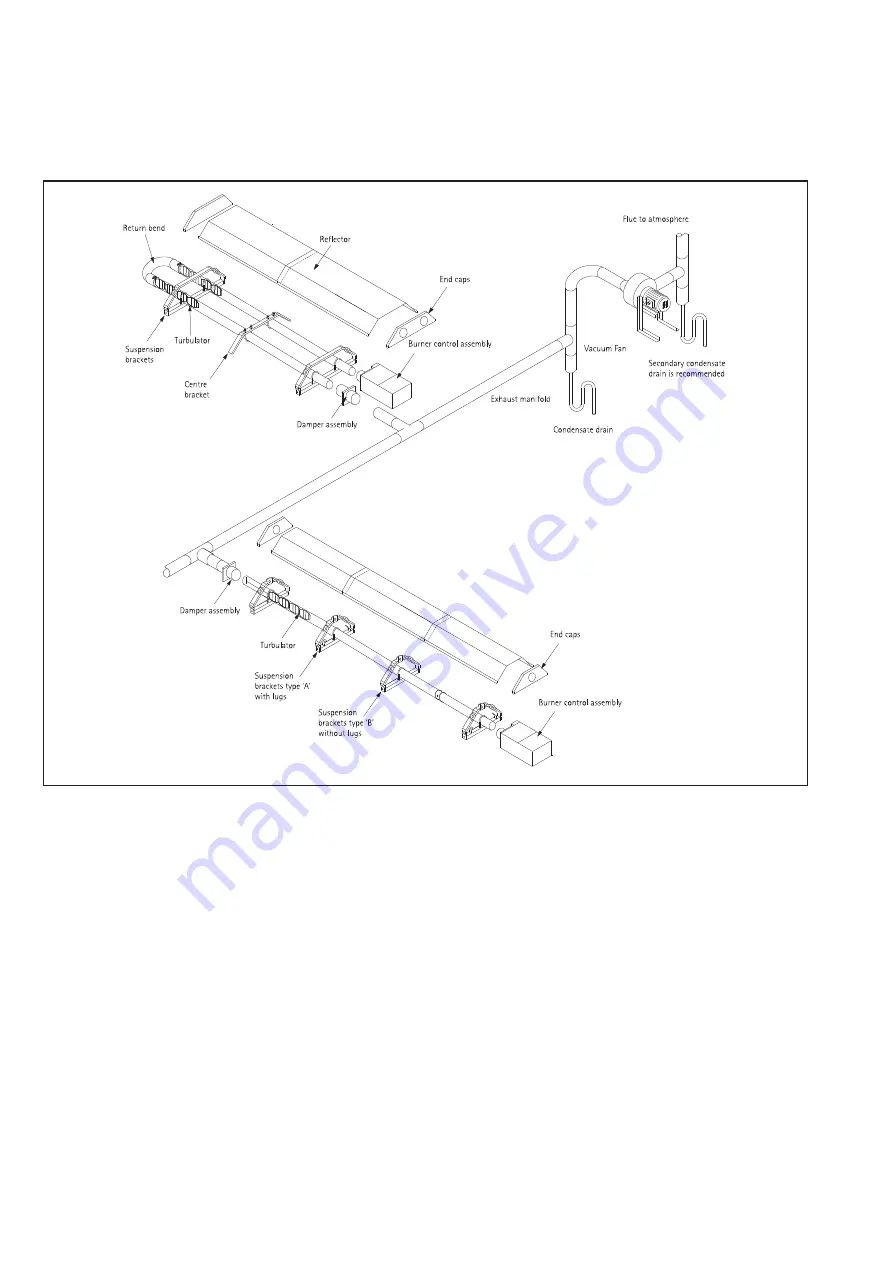

3 Manifold assembly

2 Instructions and installation

After fixing the heaters in the desired

position, the manifold system should be

laid out on the floor, where possible, to

the design layout before erecting.

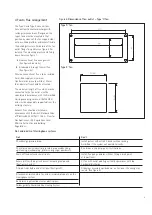

After allowing for a minimum of 75mm

(3in) of penetration of the fitting into the

tube, cut the tubes to the lengths required

and remove all burrs and wipe off any

grease or oil with a clean rag.

Secure the joint by drilling through

the tube and fitting and fix with three

pop rivets at 12 o’clock, 4 o’clock and

8 o’clock positions. 3-5mm (

3

/

16

in)

diameter pop rivets are recommended.

(See figure 3)

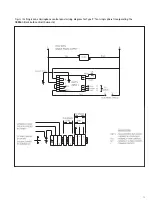

3.2 Damper assembly

The damper assembly secured to

the outlet end of the heater unit

must be located with its damper blade

vertical and left in the closed position.

The manifold tube to be sealed and

secured (as described in figures 2

and 3) to the damper assembly.

For damper assembly see figure 4.

3

Содержание Herringbone HB

Страница 1: ...HERRINGBONE HB COMBINED FLUE SYSTEM...

Страница 14: ...Figure 12b Wiring diagram for Type 0 fan single phase 13...