If ignition is successful the flame is detected

by the flame sensing probe and the ignition

spark is switched off. The amber

burner on

lamp indicates that the gas solenoid valve

is energised.

If ignition is unsuccessful the gas valve is

closed and the spark ignition de-energised

after approximately 4 seconds. After

unsuccessful ignition attempt the electronic

sequence controller will lock-out the red

mains on

lamp only will remain illuminated.

To reset this lock-out condition, switch

the power supply to the system, wait until

the fan stops completely then restart it. If

repeated lock-out occurs, investigate the

cause.

Note

If an individual burner assembly unit

is switched off and reconnected it cannot

restart. The fan must stop running before the

burner can be restarted.

To shut down the heaters switch off the

power supply to the system. Automatic

control of the heating system is achieved

through the lockable control panel,

incorporated in the electrical supply, which

may contain a time switch, black bulb

controller with day and night settings, a 3

position mode switch giving constant on/off

auto control and fan starter. It is essential to

allow a delay of 30 seconds after switching

off heaters before attempting to restart the

system.

If at any time after completion of the start

up sequence loss of flame should occur, the

electronic sequence controller will attempt

to re-ignite. If this is unsuccessful, heater

lock-out will occur.

To set the burner gas pressure

Close gas valve. Unplug mains input

connector to heater. Unscrew the fixing

screws of the safety control housing lid and

remove pressure test point screw and

connect a ‘U’ tube manometer to the

pressure test nipple located on the

combination valve. Remove the cover from

the pressure regulator to reveal the

adjusting screw.

Replace mains input connector, open gas

valve and start system.

Using a suitable screwdriver, adjust the

pressure regulator, turning the screw

clockwise to increase the pressure or

anti-clockwise to decrease the pressure.

Set the burner pressure to the required

figure given on the data label. Switch off

the heater by pulling out the mains

connector. Disconnect ‘U’ tube manometer

and refit screw in pressure test nipple. Refit

cover of pressure regulator. Replace cover

plate on safety control housing and refit

screws.

Burner ignition

To re-ignite heater, switch system off at

control panel. Wait until fan stops

completely and then restart system.

Re-ignition

Check the operation of the flame safeguard

equipment as follows:

With the heater running normally switch off

the gas supply at the appliance isolating

valve. Observe that the

burner on

lamp

extinguishes within 1 second. After a purge

period of approximately 9 seconds the

heater should attempt to re-light and if the

gas isolating valves have been left off,

lock-out should occur, indicated by power

light only being illuminated and fan

running.

Vacuum proving switch

Check the operation of the vacuum proving

switch as follows:

With the heater running normally, pull out

the mains input connector. Pull off the

silicone tube connecting the vacuum switch

to the combustion chamber. Observe for at

least 20 seconds that there is no attempt to

re-ignite. Then replace the silicone tube.

Replace the safety control housing lid and

reconnect the mains input connector.

To re-ignite each heater in the system, the

fan must stop running. Switch system off

at the control panel. Wait until fan stops

completely and then restart system.

Repeat the above procedure for each of the

heater units in the heating system.

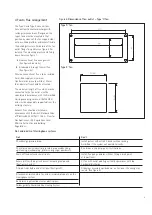

Balancing system

Important

When all the heaters have been

commissioned as above, the vacuum settings

must be finally balanced in the hot condition.

Start all burners up and allow them to run

for at least 20 minutes. With the use of a ‘U’

tube manometer determine vacuum reading

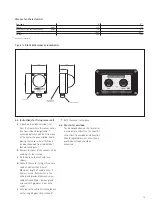

at the damper assembly on each heater. (See

figure 4 for vacuum test point)

The damper should be readjusted and set at

a hot condition reading as shown in figure 10

for the appropriate size heater and model.

It will be noted that the emitter has a

tendency to bow when hot, this is normal

and quite acceptable.

10

Содержание Herringbone HB

Страница 1: ...HERRINGBONE HB COMBINED FLUE SYSTEM...

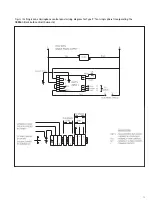

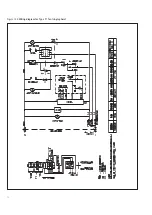

Страница 14: ...Figure 12b Wiring diagram for Type 0 fan single phase 13...