American-Lincoln Technology

1-9

ATS 46/53 Troubleshooting Guide

TROUBLESHOOTING TABLE

PROBLEM

PROBABLE CAUSE

REMEDY

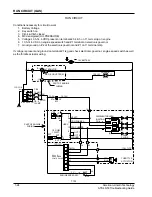

Squeegee slow or will

not lift

1. Low hydraulic oil level

2. Squeegee obstructed

3. Damaged valve and/or coil

4. Damaged check valve

5. Damaged squeegee cylinder

1. Inspect the oil level in the reservoir

and add oil until visible in the sight

gauge.

2. Remove obstruction.

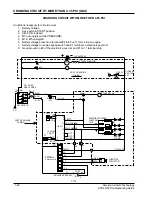

3. Check the continuity of SV4 coil on the

cylinder control valve. With a

the harness leads to the coil,

scrub deck lift switch.

"RAISE" position,

12volts. I

required. If the voltage reading

i

SV4. Repair or replace

the valve and/or coil.

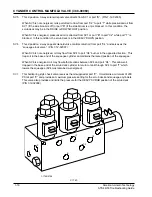

4. Install a pressure gauge as port "C3"

cylinder control manifold. With

on and squeegee switch

position, the gauge

If the reading

O-ring on

SV3, SV4, and SV5 and repair or

replace the cartridges as required. If the

solenoid valves appear functional and

the condition remain, replace the check

valve (CV1).

5. If the condition remains after the above

efforts, repair or replace the squeegee

cylinder.

across

voltmeter

activate the

With the switch in the

the meter should read

f

the voltage reading is 0, inspect the

harness and scrub deck switch and

replace as

s 12, inspect

on the

the machine

in the "LOWER"

should read 200 ± 25 PSI.

is below 175 PSI, inspect the

Squeegee will not lower

1. Low hydraulic oil level

2. Squeegee obstructed

3. Low hydraulic oil level

4. Squeegee obstructed

5. Damaged valve and/or coil

1.

2. Remove obstruction

Inspect the oil level in the reservoir and add

oil until visible in the sight gauge.

3. Check the continuity of SV6 coil on the cylinder

control valve. With a voltmeter across the

harness leads to the coil, activate the scrub

deck lift switch. With the switch in the "LOWER"

position, the meter should read 12volts. If the

voltage reading is 0, inspect the harness and

scrub deck switch and replace as required. If

the voltage reading is 12, inspect SV4. Repair

or replace the valve and/or coil as required.

4. Install a pressure gauge as port "C3" on the

cylinder control manifold. With the machine on

and squeegee switch in the "LOWER" position,

the gauge should read 200 ± 25 PSI. If the

reading is below 175 PSI, inspect the O-ring

on SV3, SV4, and SV5 and repair or replace

the cartridges as required. If the solenoid

valves appear functional and the condition

remain, replace the check valve (CV1).

5. If the condition remains after the above efforts,

repair or replace the squeegee cylinder.

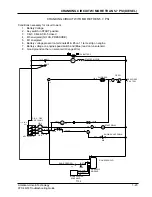

Squeegee drifts down

1. Damaged solenoid valve

2. Damaged deck cylinder

1. Inspect SV6 in the cylinder control valve for

O-ring damage and debris. Repair or replace.

2. Repair or replace the squeegee cylinder.