CLARKE TECHNOLOGY Operator's Manual - Ultra Speed Burnisher

Page -9 -

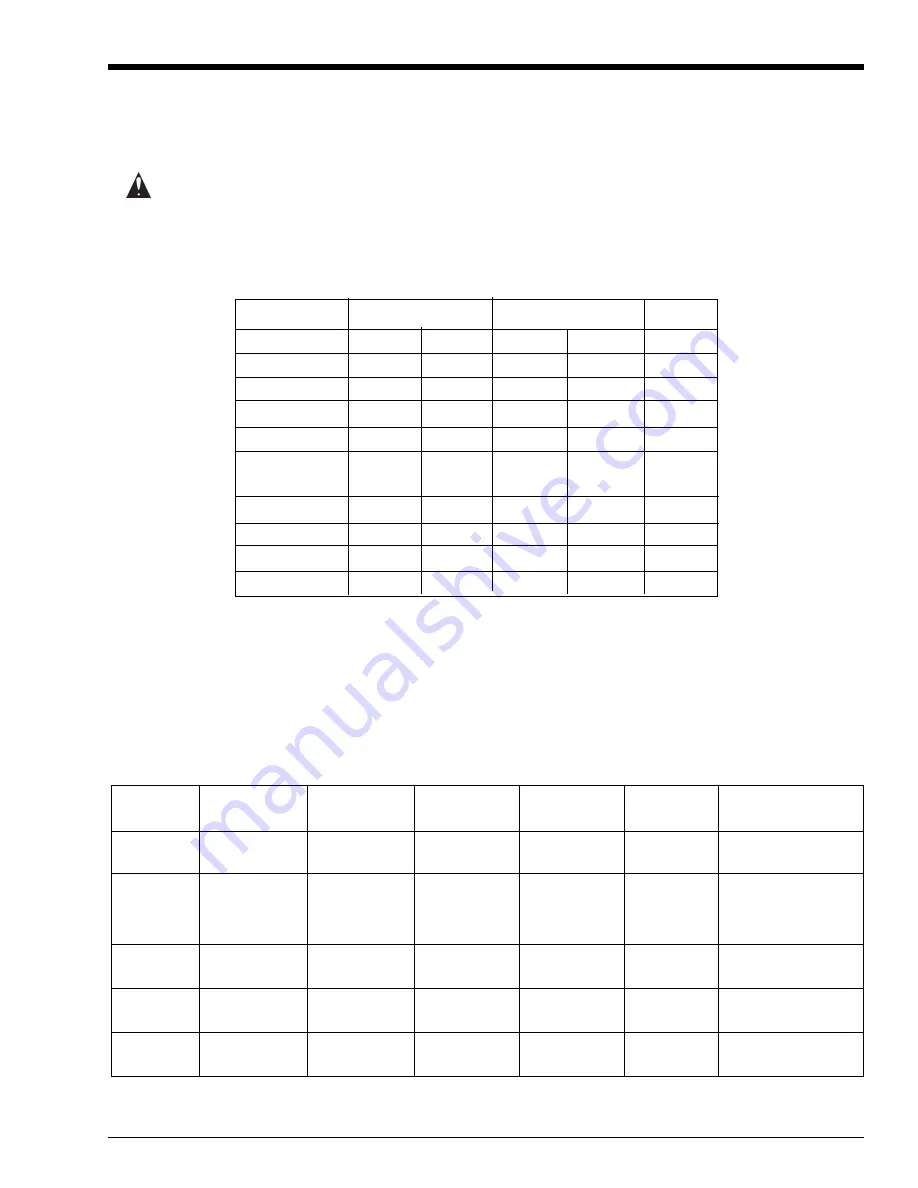

19" (48cm) 3M Burnishing Pad Selection Chart

Part No.

Description

Application

Use

RPM

Color

Finish

976289

Top Line

Burnish

Dry

1500-3000

Peach

Hard finish/high traffic

Soft finish/low traffic

976326

Natural Blend

Burnish

Dry

1500-3000

Off White

Hard finish/high traffic

Soft finish/low traffic

High traffic/low

Maintenance

976235

UHS Tan

Burnish

Dry

1500-3000

Tan

Hard finish/high traffic

Buffer

Wet-look hard finish

976236

UHS Aqua

Burnish

Dry

1500-3000

Aqua

Soft finish/low traffic

Buffer

Wet-look soft finish

976234

SHS Buffer

Buff

Dry/Spray

600-1500

Beige

Glossy finish

Spray

The direct drive electric burnishers are floor polishing machines. They are operated by moving them

forward and backward across the floor.

Note: Do not use the machine for wet scrubbing.

FEATURES AND SPECIFICATIONS

CAUTION:

To prevent serious damage to the floor surface, make sure the machine is

always moving forward or backward when the pad driver is in contact with

the floor.

Specifications:

Part Number

01139B

01140B

01138B

01141B

01142B

Voltage (V)

120

230

120

230

120

Frequency (Hz)

50/60

50/60

50/60

50/60

50/60

Current (A)

15

8

15

8

15

Pad Driver

20"

51cm

20"

51cm

20"

Burnishing

20"

51 cm

20"

51 cm

20"

Swath

Pad Speed (rpm)

1500

15000

2000

2000

2500

Motor Power

1.5 hp

1.1 kW

1.5 hp

1.5 kW

1.5 hp

Power Cable

75'

23 m

75'

23 m

75'

Weight

92.5 lbs.

42 kg

92.5 lbs.

42 kg

92.5 lbs

Model US 1500

US 2000 US 2500

Содержание 120V

Страница 34: ...NOTES ...