f) The boiler water temperature is too

low or Water temperature difference

between supply and return may be

more than 20ºF

d) Burn smaller wood, split wood,

and/or dryer wood. Build a hotter

fire. Remember that more wood

does not always equate to more

heat.

e) Adjust and/or replace load door seal

and/or Air Valve

f) Raise the boiler operating

temperature, (Max 200º F)

8. The boiler burns more wood than

usual

a) The wood has a higher moisture

content level than normal.

b) The wood is dry but has less weight

per piece of wood (soft wood).

c) The heat exchanger needs cleaned.

a) Try burning drier wood.

b) Try burning hard wood.

c) Clean the heat exchanger.

9. The pressure relief valve is releasing

(Boiler pressure keeps rising)

a) Pressure reducing valve is

malfunctioning.

b) There is not enough expansion

capacity.

c) The domestic coil is leaking.

a) Replace pressure reducing valve.

b) Add an expansion tank or replace a

malfunctioning one.

c) Replace or isolate the domestic coil.

10. There is smoke or creosote leaking

out of air inlet connection. (Pre-2014

Boilers)

a) The air valve assembly has been

moved of knocked out of position.

a) Reposition and tighten the air valve

and reseal the sleeve where enters

the boiler. Be careful not to knock

the air valve out of position when

loading fuel into the boiler.

11. There is excessive creosote

buildup on boiler vessel located behind

the lower front inspection door area.

a) The fire box is being filled too full for

the heat demand.

b) There may be a blockage in the flue,

cyclone, heat exchanger, or

refractory.

c) The wood logs are too small and/or

have very low moisture content.

d) Load door seal or air valve seal is

leaking.

e) The boiler is operated with water

temperature too low. The stack

temperature may not be high

enough.

a) Fill the fire box only half full or

enough to burn for eight hours.

b) Remove ash from fire box and

refractory. Clean the heat

exchanger, cyclone, or flue.

c) Burn larger wood, unsplit wood,

and/or green wood.

d) Adjust load door, fix, or replace air

valve.

e) Raise the boiler operating

temperature to 180-190 F

12. Steel has etching or pitting

a) Heating domestic water in the

summer time with a carbon steel

boiler.

a) Increase operating temperature in

boiler. Only use small amounts of

very dry wood to burn straight

through the fuel charge with no

cycling.

- 61 -

Содержание wood gun E100 SF

Страница 2: ......

Страница 24: ...Photo Smoke flap installed 19 ...

Страница 46: ...Steel Center Brick 8 Inch 41 ...

Страница 49: ...Appendix A Boiler Specification Diagram 44 ...

Страница 50: ... 45 ...

Страница 51: ... 46 ...

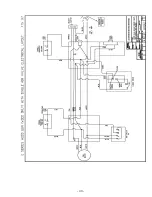

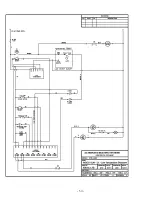

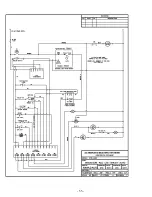

Страница 53: ...Appendix B Wiring Diagrams 48 ...

Страница 54: ... 49 ...

Страница 55: ... 50 ...

Страница 56: ... 51 ...

Страница 57: ... 52 ...

Страница 58: ... 53 ...

Страница 59: ... 54 ...

Страница 60: ... 55 ...

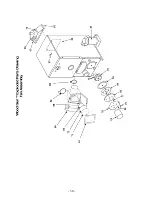

Страница 61: ...Appendix C Exploded Parts Drawings 56 ...

Страница 63: ... 58 ...

Страница 68: ...Appendix F Boiler Piping and Ducting Examples 63 ...

Страница 69: ...Wood Gun Air Inlet Ducting Installations 64 ...