506724-01

Page 16 of 57

Issue 1108

6. Promptly apply solvent cement to end of pipe and inside

socket surface of fitting. Cement should be applied

lightly but uniformly to inside of socket. Take care to

keep excess cement out of socket. Apply second coat

to end of pipe.

7. Immediately after applying last coat of cement to pipe,

and while both inside socket surface and end of pipe

are wet with cement, forcefully insert end of pipe into

socket until it bottoms out. Turn PVC pipe 1/4 turn during

assembly (but not after pipe is fully inserted) to distribute

cement evenly. Do not turn ABS or cellular core pipe.

NOTE:

Assembly should be completed within 20 seconds

after last application of cement. Hammer blows should not

be used when inserting pipe.

8. After assembly, wipe excess cement from pipe at end

of fitting socket. A properly made join will show a bead

around its entire perimeter. Any gaps may indicate an

improper defective assembly due to insufficient solvent.

9. Handle joints carefully until completely set.

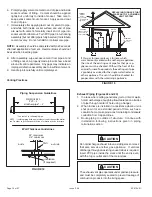

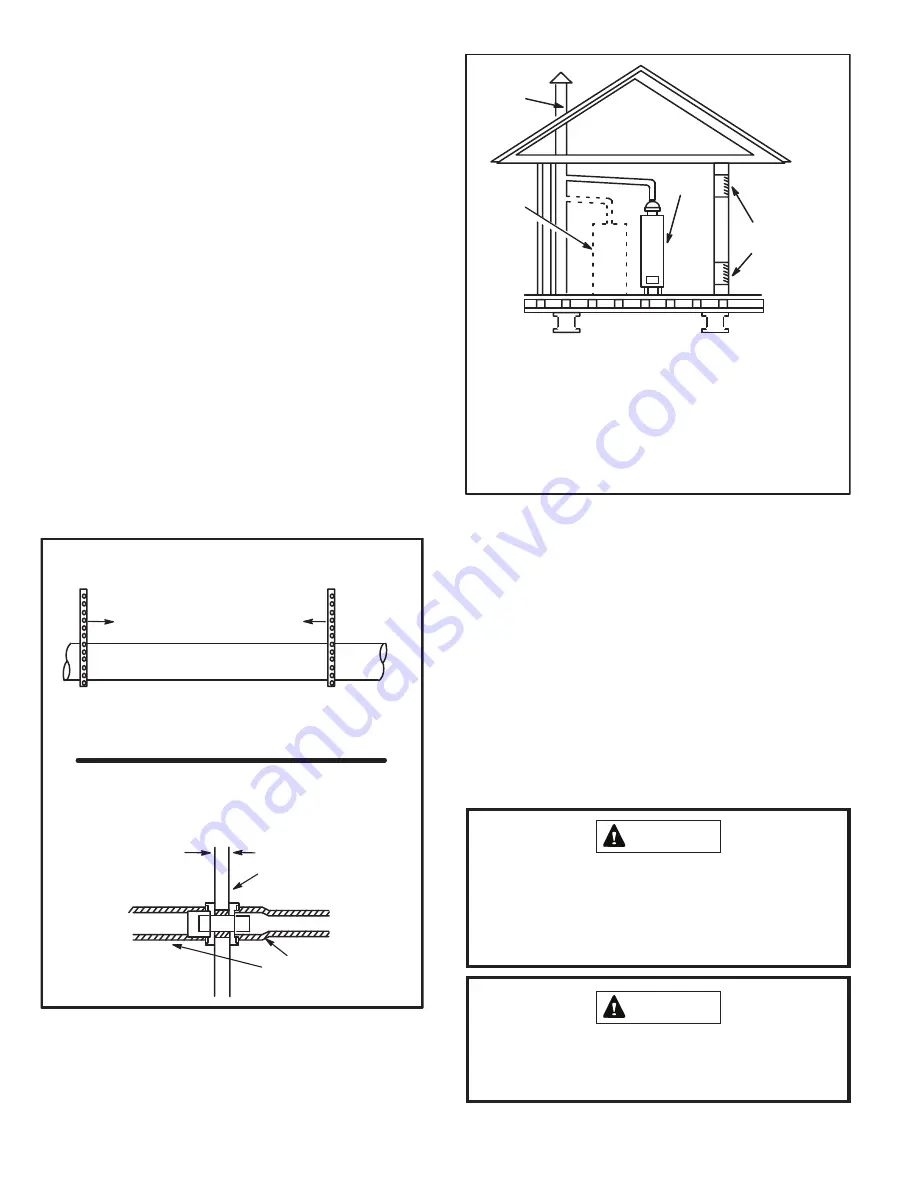

Exhaust Piping (Figures 22 and 23)

1. In areas where piping penetrates joist or interior walls,

hole must be large enough to allow clearance on all sides

of pipe through center of hole using a hanger.

2. When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a

vacation home, make provisions for draining condensate

collection from trap and lines.

3. Route piping to outside of structure. Continue with

installation following instructions given in piping

termination section.

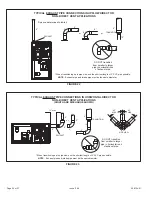

The exhaust vent pipe operates under positive pressure

and must be completely sealed to prevent leakage of

combustion products into the living space.

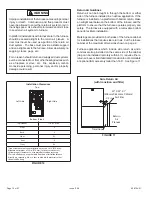

CAUTION

Do not discharge exhaust into an existing stack or stack

that also serves another gas appliance. If vertical

discharge through an existing unused stack is required,

insert PVC pipe inside the stack until the end is even

with the top or outlet end of the metal stack.

CAUTION

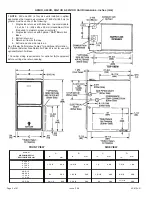

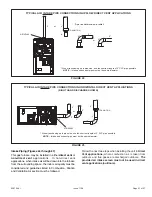

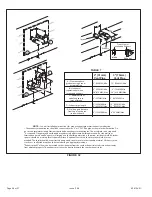

Venting Practices

FIGURE 18

* See table 2 for allowable pipe.

Piping Suspension Guidelines

NOTE

− Isolate piping at the point where it exits the outside wall or

roof in order to prevent transmission of vibration to the structure.

SCHEDULE 40

PVC − 5’

all other pipe* − 3’

Wall

e

d

i

s

t

u

o

e

d

i

s

n

i

24" maximum

3/4" minimum

Wall Thickness Guidelines

insulation

(if required)

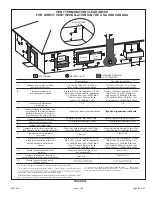

CHIMNEY

OR GAS

VENT

(Check sizing

for remaining

appliance)

FURNACE

(Removed from

from common

vent system)

WATER

HEATER

OPENINGS

(To Adjacent

Room)

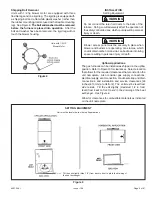

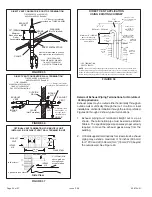

If this gas furnace replaces a furnace which

was commonly vented with another gas appliance,

the size of the existing vent pipe for that gas ap-

pliance must be checked. Without the heat of the

original fur nace flue products, the existing vent pipe

is probably oversized for the single water heater or

other appliance. The vent should be checked for

proper draw with the remaining appliance.

FIGURE 19

REPLACING FURNACE THAT

WAS PART OF A COMMON

VENT SYSTEM