507335-01

Page 6 of 44

Issue 1624

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

In addition to the requirements outlined previously, the

following general recommendations must be considered

when installing one of these furnaces:

•

Place the furnace as close to the center of the air

distribution system as possible. The furnace should

also be located close to the chimney or vent termination

point.

•

Do not install the furnace where drafts might blow

directly into it. This could cause improper combustion.

•

Do not block the furnace combustion air openings with

clothing, boxes, doors, etc. Air is needed for proper

combustion and safe unit operation.

•

When the furnace is installed in an attic or other

insulated space, keep insulation away from the furnace.

NOTE:

The Commonwealth

of

Massachusetts stipulates

these additional requirements:

•

Gas furnaces shall be installed by a licensed plumber

or fitter only.

•

The gas cock must be “T handle” type.

•

When a furnace is installed in an attic, the passageway

to and service area surrounding the equipment shall be

floored.

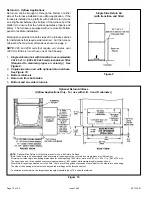

Combustion, Dilution & Ventilation Air

In the past, there was no problem in bringing in sufficient

outdoor air for combustion. Infiltration provided all the air that

was needed. In today’s homes, tight construction practices

make it necessary to bring in air from outside for combustion.

Take into account that exhaust fans, appliance vents,

chimneys, and fireplaces force additional air that could be

used for combustion out of the house. Unless outside air

is brought into the house for combustion, negative pressure

(outside pressure is greater than inside pressure) will build

to the point that a downdraft can occur in the furnace vent

pipe or chimney. As a result, combustion gases enter the

living space creating a potentially dangerous situation.

In the absence of local codes concerning air for combustion

and ventilation, use the guidelines and procedures in this

section to install these furnaces to ensure efficient and safe

operation. You must consider combustion air needs and

requirements for exhaust vents and gas piping.

A portion of this information has been reprinted with

permission from the National Fuel Gas Code (ANSI-Z223.1).

This reprinted material is not the complete and official

position of the ANSI on the referenced subject, which is

represented only by the standard in its entirety.

Product Contains Fiberglass Wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you to

fiberglass wool. Breathing this may cause lung cancer.

(Fiberglass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin, and

eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Allied Air Enterprises, Inc.

215 Metropolitan Drive

West Columbia, SC 29170

WARNING

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rusting

and premature heat exchanger failure. Excessive

exposure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substances in the combustion

air supply:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine base swimming pool chemicals

Water softening chemicals

De-icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

WARNING

Содержание 80G2UH-V

Страница 29: ...507335 01 Page 29 of 44 Issue 1624 ADJUSTING AIRFLOW Table 11 ...

Страница 37: ...507335 01 Page 37 of 44 Issue 1624 Burner Combustion Air Inducer Assembly and Heat Exchanger Removal Figure 38 ...

Страница 41: ...507335 01 Page 41 of 44 Issue 1624 Wiring Diagram Figure 41 ...

Страница 42: ...507335 01 Page 42 of 44 Issue 1624 Typical Field Wiring Diagram Figure 42 ...

Страница 43: ...507335 01 Page 43 of 44 Issue 1624 Start Up Performance Check List UNIT SET UP ...

Страница 44: ...507335 01 Page 44 of 44 Issue 1624 UNIT OPERATION ...