507335-01

Page 26 of 44

Issue 1624

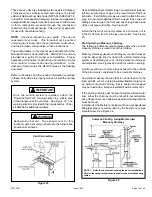

4. Before connecting the thermostat, check to make sure

the wires will be long enough for servicing at a later

date. Make sure that thermostat wire is long enough

to facilitate future removal of blower for service.

5. Complete the wiring connections to the equipment. Use

the provided unit wiring diagram and the field wiring

diagram shown in Figure 42. Use 18 gauge wire or

larger that is suitable for Class II rating for thermostat

connections.

6. Electrically ground the unit according to local codes or,

in the absence of local codes, according to the current

National Electric Code (ANSI/NFPA No. 70). A green

ground wire is provided in the field make-up box.

NOTE:

This furnace contains electronic components that

are polarity sensitive. Make sure that the furnace is wired

correctly and is properly grounded.

7. One line voltage “EAC” 1/4” spade terminal is provided

on the furnace integrated control. Any electronic air

cleaner or other accessory rated up to one amp can

be connected to this terminal with the neutral leg of the

circuit being connected to one of the provided neutral

terminals. See Figure 42 for control configuration.

This terminal is energized when the indoor blower is

operating.

8. One line voltage “HUM” 1/4” spade terminal is provided

on the furnace integrated control. Any humidifier rated

up to one amp can be connected to this terminal with

the neutral leg of the circuit being connected to one of

the provided neutral terminals. See Figure 42 for control

configuration. This terminal is energized in the heating

mode whenever the combustion air inducer is operating.

9. Install the room thermostat according to the instructions

provided with the thermostat. If the furnace is being

matched with a heat pump, refer to the instruction

packaged with the dual fuel thermostat.

Indoor Blower Speeds

1. When the thermostat is set to “FAN ON,” the indoor

blower will run continuously at approximately 50% of the

second stage cooling speed when there is no cooling

or heating demand.

2. When this unit is running in the heating mode, the indoor

blower will run on the heating speed designated by

the positions of DIP switches 1 (A,B,C,D) of the HEAT

jumper plug.

3. When there is a cooling demand, the indoor blower will

run on the cooling speed designated by the positions of

DIP switches (A, B, C, D) of the COOL jumper plug.

Generator Use - Voltage Requirements

The following requirements must be kept in mind when

specifying a generator for use with this equipment:

•

The furnace requires 120 volts ± 10% (Range: 108 volts

to 132 volts).

•

The furnace operates at 60 Hz ± 5% (Range: 57 Hz to

63 Hz).

•

The furnace integrated control requires both polarity

and proper ground. Both polarity and proper grounding

should be checked before attempting to operate the

furnace on either permanent or temporary power.

•

Generator should have a wave form distortion of less

than 5% RHD.

Electrical Wiring

Risk of electrical shock. Disconnect electrical power

at the circuit breaker or service panel before making

electrical connections. Failure to disconnect power

supplies can result in property damage, personal injury,

or death.

WARNING

The furnace must be grounded and wired in accordance

with local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

and/or CSA C22.1 Electrical Code (latest edition) if an

external electrical source is utilized.

Table 10

Содержание 80G2UH-V

Страница 29: ...507335 01 Page 29 of 44 Issue 1624 ADJUSTING AIRFLOW Table 11 ...

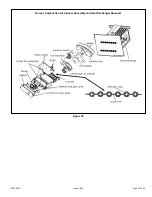

Страница 37: ...507335 01 Page 37 of 44 Issue 1624 Burner Combustion Air Inducer Assembly and Heat Exchanger Removal Figure 38 ...

Страница 41: ...507335 01 Page 41 of 44 Issue 1624 Wiring Diagram Figure 41 ...

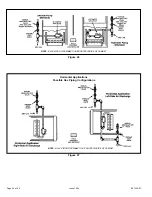

Страница 42: ...507335 01 Page 42 of 44 Issue 1624 Typical Field Wiring Diagram Figure 42 ...

Страница 43: ...507335 01 Page 43 of 44 Issue 1624 Start Up Performance Check List UNIT SET UP ...

Страница 44: ...507335 01 Page 44 of 44 Issue 1624 UNIT OPERATION ...