20

45-074, REV. 5/18

Equipment damage hazard.

A chipped pinion shaft will affect machine

performance.

Do not drop the pinion shaft onto a hard

surface or it may chip.

NOTICE

The small bearing cup in the housing and

the large bearing cup in the gear cap will

need to be removed with a bearing puller.

8. Wipe as much grease out of the housing as possible

with a rag and inspect for any foreign particles.

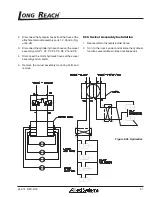

9. The oil seals may now be serviced. Note the orienta-

tion of the seals. (Figure 5-18)

Seals

Housing Cover

Figure 5-18, Pinion Shaft Seals

10. Remove the worm cap and motor adapter. Make note

of any installed shims. Capscrews are installed with

Loctite, so use a long-handled wrench to break them

loose. Use a large screwdriver and hammer to sepa-

rate the worm cap from the housing. Note any installed

shims. (Figure 5-19)

Capscrew

Capscrew

O-Ring

O-Ring

Motor Adapter

End Cap

Shim

Shim

Shim

Coupling

Figure 5-19, Worm Cap/Motor Adapter

Equipment damage hazard.

Damage to the worm cap or housing could

reduce machine performance or void the

warranty.

Do not damage the machined surfaces of

the worm cap and housing.

11. The seal in the motor adapter can now be replaced.

(Figure 5-20)

Seal

Motor Adapter

Figure 5-20, Motor Adapter Seal

12. Using a rubber mallet, lightly tap on the extended end

of the worm gear shaft and remove it through the

housing.