BRIDGE DECK FINISHER SET-UP GUIDE - 069596

Page 9

BDF Assembly & Set-up

• The depth and penetration required will vary according to

job specifications.

• Pitching the front end of the drum higher allows the roller

tamper to remain parallel to the concrete surface when the

rear of the machine is raised at the beginning of the pour,

with the max recommended depth is 3/16 inch.

CARRIAGE TRAVEL DISTANCE

• Adjust the carriage travel distance by positioning the chain

lugs on the

upper and

lower travel

chains (SEE

PICTURE).

• Manually

push with

your hand,

the top striker

plate of the shifter until the reversing valve shifts. Manually

push with your hand, the bottom striker plate of the shifter

until the reversing valve shifts. Do this for both directions of

carriage travel.

• Place the paving carriage at the desired travel distance at

the idler end of the machine and stop the carriage. Hold

back the striker plate and attach the chain lug next to the

striker plate on the top of the travel chain.

• Place the paving carriage at the desired travel distance at

the power unit end of the machine and stop the carriage.

Hold back the striker plate and attach the chain lug next to

the striker plate on the bottom of the travel chain.

• Once the chain lugs have been installed, to set the paving

carriage pivot shift

movement on the idle

end, slide a striker

target or shifter paddle

onto the carriage rail

at the desired point the

carriage needs to shift.

• After the shifting rod

makes contact with

target, the paving

roller reversing valve

will not engage at this

time, TO ENGAGE the

shift in the reversing

valve, move the paddle

approximately 1”- 2”,

until the rod spring shifts the reversing valve and the lower

carriage shifts.

• Tighten the T-Bolt to lock the Striker target or shifter paddle

in place.

• REPEAT the previous 3 steps for the power unit side of

the machine.

• The bottom thrust rollers on the hanger frame, positioned

under the carriage rail can be tightened so that the rollers

have a slight pressure on the carriage rail, allowing you to

turn them by hand.

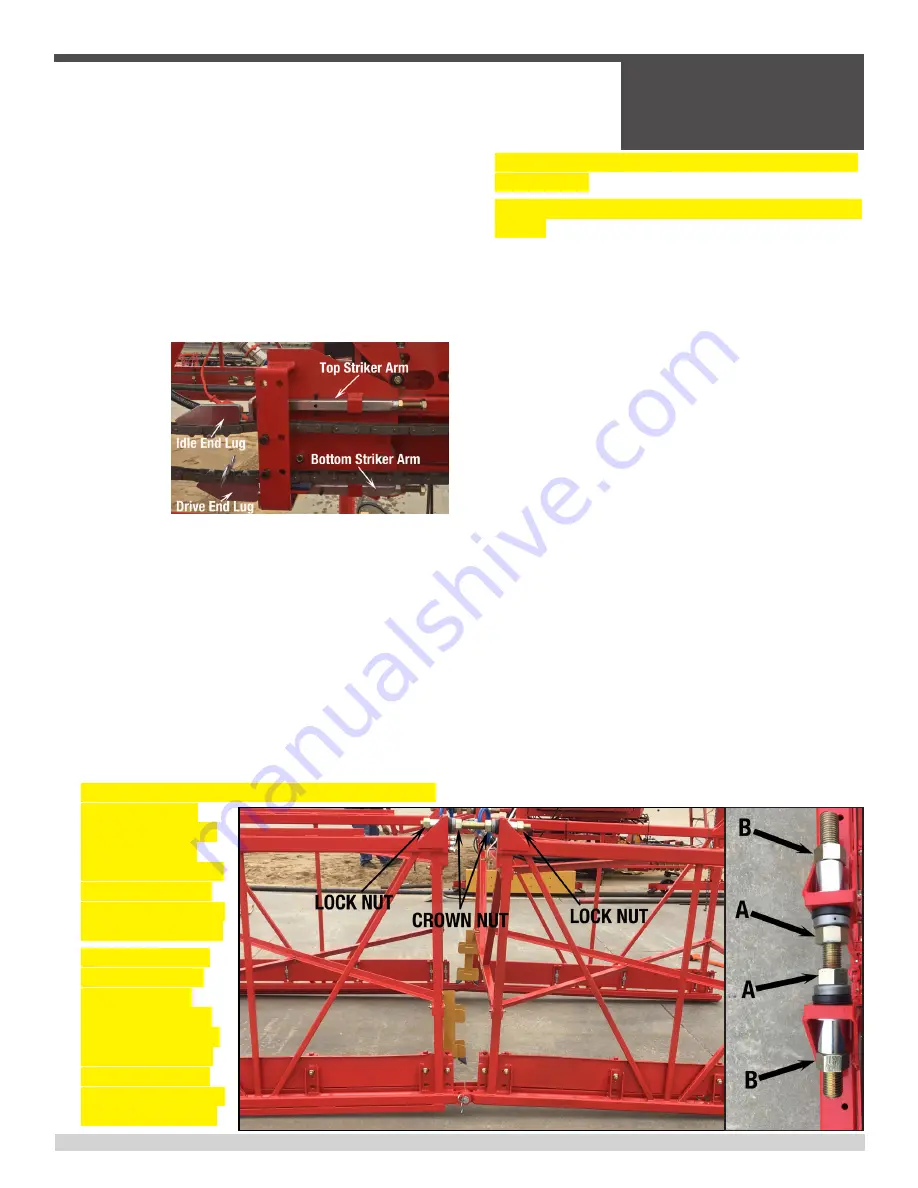

MANUAL / POWER / CROWN BOLT ADJUSTMENT

• The insert frame section hinge point or truss connection

should be positioned on the machine to coincide directly

above the crown center.

• The paving carriage should be moved to the crown position,

allowing for deflection of the truss frame with the full weight

of the carriage.

• Note the measurement from a grade point on the deck to

the top of the carriage rail on both sides of the machine.

• The manual/power/crown bolts can be adjusted for the

machine frame slope to the specified deck crown or center

grade slope (1.5%,2%, 2.5%...).

• For the crown bolts, adjust them ½” at a time and alternate

sides (SEE PICTURE) which allows a slight shift with the

angle change.

• Loosening lock nuts “B” on both sides, allows you to adjust

the crown nuts “A” and vice versa..