SFBTT20-IT BOBTAIL® Hydraulic Tool

(HK1121)

Alcoa Fastening Systems

11

M

M

AINTENANCE

AINTENANCE

•

The efficiency and life of your tool depends on proper

maintenance. Please read this section completely

before proceeding with maintenance and repair. Use

proper hand tools in a clean and well-lighted area.

Only standard hand tools are required in most cases.

Where a special tool is required, the description and

part number are given.

•

While clamping tool or parts in a vise, and when

parts require force, use suitable soft materials to

cushion impact. For example, using a half-inch brass

drift, wood block and vise with soft jaws greatly

reduces possibility of damaging tool. Remove compo-

nents in a straight line without bending, cocking or

undue force. Reassemble tool with the same care

.

Sealants, Lubricants, Service Kits

•

See

S

S

PECIFICATIONS

PECIFICATIONS

for fluid type. Dispose of fluid

in accordance with local environmental regulations.

Recycle steel, aluminum, and plastic parts in accor-

dance with local lawful and safe practices.

•

Rub Slic-Tite®* with PTFE thread compound, or

equivalent, on pipe plug threads and quick connect

fitting.

•

Smear LUBRIPLATE® 13OAA*, or equivalent lubri-

cant, on O-Rings and mating surfaces to aid assem-

bly and to prevent damage to O-Rings.

(LUBRIPLATE 13O-AA is available in a tube as

Huck P/N 502723.)

•

Each Service Kit contains perishable parts for your

specific tool. As foreseeable use may indicate, keep

extra kits (O-rings, Back-up Rings, other standard

items) and tool parts in stock. When stock is deplet-

ed, you can get kit items from any regular retailer of

these items. See kit parts list for: O-ring size

(AS568- number); material; durometer.

P

REVENTIVE

M

AINTENANCE

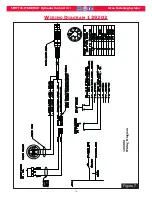

System Inspection

Operating efficiency of the tool is directly related to the

performance of the complete system, including the tool

with nose assembly, hydraulic hoses, trigger and con-

trol cord, and POWERIG. Therefore, an effective pre-

ventive maintenance program includes scheduled

inspections of the system to detect and correct minor

troubles. At the beginning of each shift/day:

• Inspect tool and nose assembly for external dam-

age.

• Verify that hydraulic hose fittings, couplings, and

electrical connections are secure.

• Inspect hydraulic hoses for damage and deteriora-

tion. Do not use hoses to carry tool. Replace hoses

if damaged.

• Observe tool, hoses, and hydraulic unit during oper-

ation to detect abnormal heating, leaks, or vibration.

• Max hydraulic fluid contamination level: NAS 1638

class 9, or ISO CODE 18/15, or SAE level 6.

POWERIG Maintenance

Maintenance instructions and repair procedures are

in the appropriate POWERIG Instruction Manual.

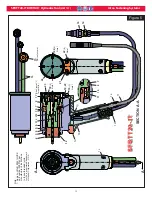

Tool Maintenance

Whenever disassembled and also at regular intervals

(depending on severity and length of use), replace all

seals, wipers, and back-up rings in tool. Service Kits,

hoses, and extra parts should be kept in stock.

Inspect cylinder bore, pistons, and piston rods for

scored surfaces and excessive wear or damage.

Replace as necessary.

Nose Assembly Maintenance

Clean nose assembly often. Dip in mineral spirits or

similar solvent to clean puller and wash away metal

chips and debris. At regular intervals, as experience

shows, disassemble nose and use a sharp "pick" to

remove imbedded particles from grooves of puller.

*

DEXRON is a registered trademark of General Motors Corp.

Quintolubric is a registered trademark of Quaker Chemical Corp.

Slic-Tite is a registered trademark of LA-CO Industries, Inc.

TEFLON is a registered trademark of DuPont Corp.

LUBRIPLATE is a registered trademark of Fiske Brothers

Refining Co.

WARNING: Inspect tool for damage or

wear before each use. Do not operate if

damaged or worn, as severe personal

injury may occur.

CAUTIONS:

- Consult MSDS before servicing tool.

- Keep dirt and other material out of

hydraulic system.

- Separated parts most be kept away from

dirty work surfaces.

- Dirt/debris in hydraulic fluid causes failure

in POWERIG® Hydraulic Unit’s valves.

CAUTION: Do not use TEFLON

®

* tape on pipe

threads. Pipe threads may cause tape to shred

resulting in tool malfunction. (Slic-Tite

®

* is

available in stick form as Huck P/N 503237.)

CAUTION: Always replace seals, wipers,

and back-up rings when tool is disassem-

bled for any reason.