SFBTT20-IT BOBTAIL® Hydraulic Tool

(HK1121)

Alcoa Fastening Systems

10

O

O

PERATING

PERATING

I

I

NSTRUCTIONS

NSTRUCTIONS

:

:

1.

Push the tool’s nose over the end of the fastener until it

bottoms out.

2.

Press the trigger and hold until the collar is swaged and

the tool’s Anvil is ejected off the collar and the tool is

released from the fastener.

WARNING: To avoid pinch

point, never place hand

between nose assembly

and work piece.

WARNING: Only use com-

patible equipment with

this tool.

W

W

RENCHING

RENCHING

-

-

UP

UP

OF

OF

P

P

IPE

IPE

T

T

HREADS

HREADS

The following table pertains to 1/8, 1/4, and 3/8 NPTF joints in this product. All turn counts listed are beyond

hand-tight. Teflon stick or equivalent (NOT tape) must be used without exception.

Pipe Thread Size

Number of Turns

1/8 NPTF

2 - 2

1

⁄ 4

1/4 NPTF

1

1

⁄ 2

- 1

3

⁄ 4

3/8 NPTF

1

1

⁄ 2

- 1

3

⁄ 4

Table 2 - Wrenching-up of Pipe Threads

L

L

IMIT

IMIT

S

S

WITCH

WITCH

A

A

DJUSTMENT

DJUSTMENT

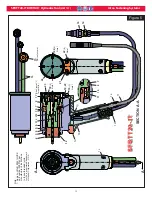

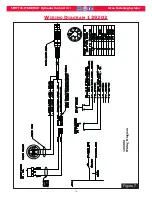

Refer to Parts List on page 12, and Figures 5 and

6 on pages 13 and 14 for identification of

Components.

NOTE: It is important to ensure that the face of the

micrometer is firmly against the Puller Head, and

the micrometer depth pin is in contact with the

Actuator Rod when measuring.

1. Check to see where the Limit Switch is set using

the Light Box and the Depth Micrometer.

2. Using an Allen wrench, remove Screw (Item 24,

Figure 5).

3. To increase the switch setting turn the Set Screw

(Item 17d, figure 6) counterclockwise; to decrease

it, turn it clockwise.

4. Adjust the switch to the specification of .430-.435”.

You will notice the Light Box light will come on

once the switch has been made.

5. Replace Screw (24).

NOTE: After tightening the Lockdown Screw,

verify the adjustment again by measuring with

the depth micrometer.

6. Once adjusted to the desired specification, discon-

nect the Light Box and reconnect the system. The

tool is now ready to drive fasteners.

TOOLS NEEDED

1. Controller or Light Box

2. Depth Micrometer

3. Allen Wrench

Light Box

Light Box

(Styles

(Styles

may vary)

may vary)

Hold micrometer face

Hold micrometer face

firmly to Puller face when

firmly to Puller face when

measuring.

measuring.